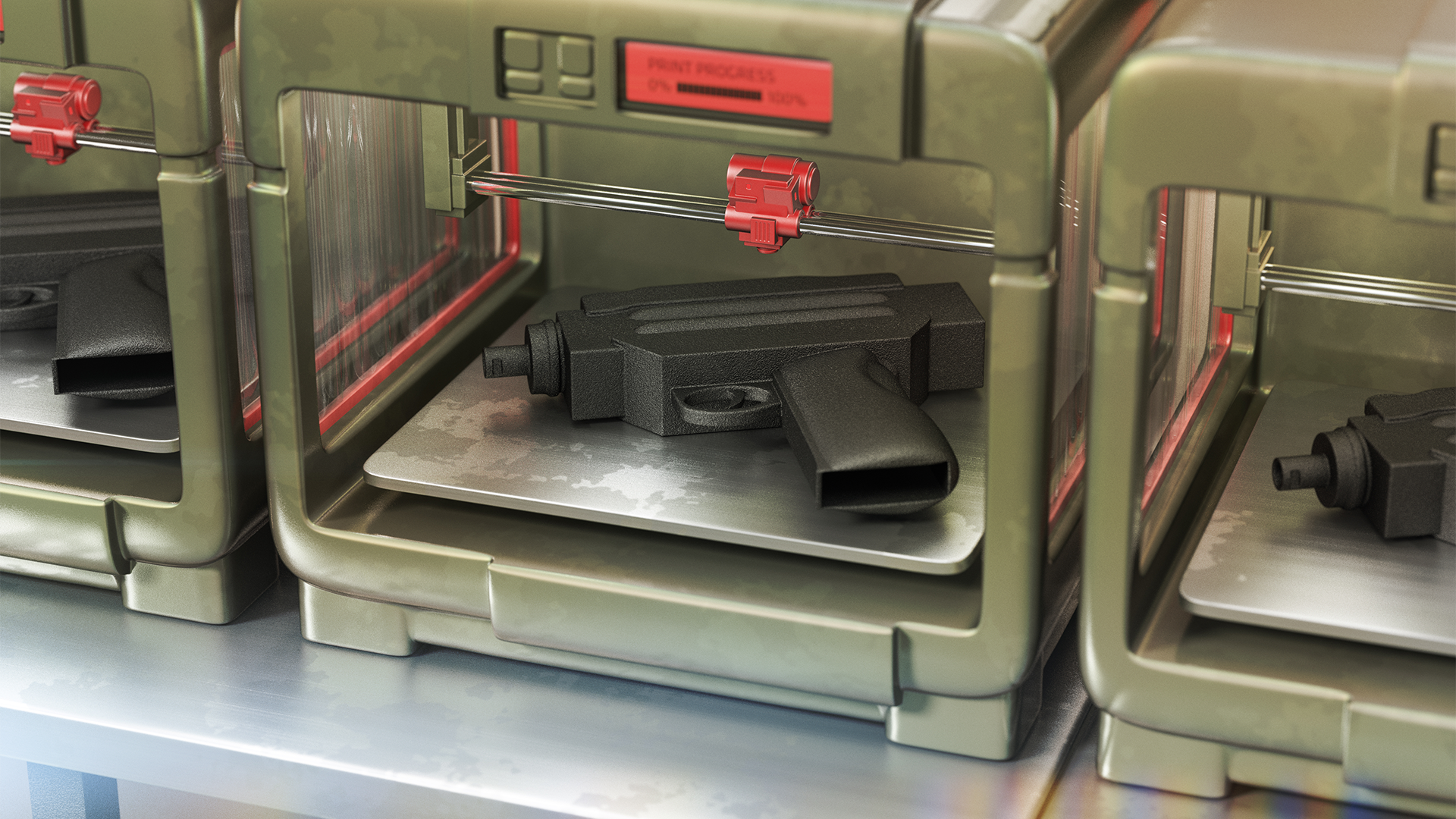

3D-printed full-auto bullpup 'ghost guns' can now be made for a couple of hundred dollars — designs have evolved dramatically outside the U.S.

The topic of 3D-printed "ghost guns" has always been one of the highest-caliber discussions worldwide — both in and out of the United States, where gun ownership is chambered in the Constitution. Things are a bit different outside the U.S., as detailed in an interesting exposé in Bloomberg — ownership of guns is highly restricted in other countries, and their manufacturing, even more so. The write-up is interesting for anyone interested in 3D printing or guns, as it details the evolution of the concept and the people behind it.

The original 3D-printed gun design was the Liberator, a one-shot pistol that would likely crack after you shot it. However, as 3D printers and their respective materials advanced, the concept of printing a "ghost gun," as they're often called, reportedly isn't nearly as difficult as it was before. These days, a decent printer, filament, and an extra few metal components are the only requirements.

Evolving gun designs to fit the mold of 3D printing was necessary, and a key element was the now-popular FCG-9 carbine, which released on October 2020 by Jacob Duygu (aka JStark1809), a now-deceased German-Kurdish member of the Deterrence Dispensed online group. This design is chambered in 9 mm and obviates the need for any factory-made gun parts — employing fasteners and other small parts using the metric standard. The only tricky bit seems to be the barrel itself, though there are multiple well-documented ways to build it.

Other evolutionary or inspired-by designs popped up soon after, such as the Rogue 9 by Immortal Design, which can have a telescoping stock and needs even fewer tailor-made metal parts; or the FGC-9 Mk II Stingray, which adds a longer barrel and definitely looks like a Serious Gun (at least, to a layman). Perhaps the most interesting of these, though, is the Brazilian-designed Urutau, which was released in August 2024 by José Carioca (aka Joseph the Parrot).

The Urutau was designed in collaboration with U.S. gun enthusiasts, as Joseph purportedly never built one himself, relying on external testing and feeback to evolve the design. It's a bullpup design that's reportedly able to fire in full-auto in its latest revision, published very recently. Among other things, its documentation includes a guide on good OpSec practices and multiple ways to build the requisite steel parts. It's estimated that one of these costs just $150 to produce.

Bloomberg's article also delves into the political side of each of the gun designs and the people around them. Needless to say, although there's a common thread in the designers' and enthusiasts' reasons, the opinions on the respective approaches aren't as universal as one might think, particularly when profit is involved. It's quite an informative read and sheds light on the rather impressive evolution of firearm 3D printing and home manufacturing throughout the world.

Follow Tom's Hardware on Google News, or add us as a preferred source, to get our latest news, analysis, & reviews in your feeds.

Get Tom's Hardware's best news and in-depth reviews, straight to your inbox.

Bruno Ferreira is a contributing writer for Tom's Hardware. He has decades of experience with PC hardware and assorted sundries, alongside a career as a developer. He's obsessed with detail and has a tendency to ramble on the topics he loves. When not doing that, he's usually playing games, or at live music shows and festivals.

-

USAFRet People..I implore you to please keep this to the technical aspect, and to not delve into the political.Reply

Thanks. -

MechWarrior Honestly, not surprising. Keep in mind, all the important items are made from metal. Barrel, bolt, springs, etc. Just the lowers and other non crucial parts are made from plastics or polymers. Full plastic ones have been tried before, but they don't last very long.Reply

Actual firearms parts are already 3D printed with titanium filaments, see HuxWrx for some of those. The equipment is still expensive overall, but eventually may come down in price. But also keep in mind, like machining be it manual or CNC, 3D printing takes a lot of time and practice, especially when you need to deal with tight tolerances and high pressures. Can the average person do this? Yes, but with a LOT of trial and error. Just because you can download the file, does not mean it will work properly or reliably. -

MechWarrior Reply

Really just depends. Especially with what materials are chosen. If the crucial components are metal and the proper alloys at that, probably thousands.DingusDog said:I wonder how many times it can go full auto before blowing up in your face. -

Zeus287 Reply

Huxwrx suppressors aren't printed with titanium filament. They're printed with a technology called Direct Metal Laser Sintering, which uses powdered metal. You're right that the machines are exorbitantly expensive, though. So much so that only one manufacturer produces nearly every 3D printed suppressor on the market (the suppressor "manufacturers" are really just designers in this case, as they contract it out to this company). Each machine costs around $1 million, so not many manufacturers have them.MechWarrior said:Honestly, not surprising. Keep in mind, all the important items are made from metal. Barrel, bolt, springs, etc. Just the lowers and other non crucial parts are made from plastics or polymers. Full plastic ones have been tried before, but they don't last very long.

Actual firearms parts are already 3D printed with titanium filaments, see HuxWrx for some of those. The equipment is still expensive overall, but eventually may come down in price. But also keep in mind, like machining be it manual or CNC, 3D printing takes a lot of time and practice, especially when you need to deal with tight tolerances and high pressures. Can the average person do this? Yes, but with a LOT of trial and error. Just because you can download the file, does not mean it will work properly or reliably.

Also, anyone can print a firearm these days with little experience. Modern 3D printers aren't like the old days of spending dozens of hours tuning a Ender to get good results. With Bambu Lab printers, and all the other models from other manufacturers that followed it, very little tuning is needed. It really has become nearly as easy as using a 2D printer. -

jg.millirem ReplyUSAFRet said:People..I implore you to please keep this to the technical aspect, and to not delve into the political.

Ignoring the societal impacts of tech is a major problem with tech culture. Having to warn people to ignore rational concerns really exemplifies this. -

USAFRet Reply

No it isn't.jg.millirem said:Ignoring the societal impacts of tech is a major black eye to tech culture.

This is a tech site. And there are many technical aspects with can be discussed here.

The social/political/legal aspects can be debated in multiple other arenas. Left unchecked, those things completely drown out the tech discussion. -

Kilofeenix Reply

I'm assuming the couple hundred buys you a metal receiver and barrel and whatnot and your pretty much just printing the plastic parts it would have anyway, and anyone worth their salt would uh salt sinter their parts.DingusDog said:I wonder how many times it can go full auto before blowing up in your face. -

arch1e I've had the good fortune to fire several firearms that had 3d printed components (or were 90% 3d printed) and they've really come along way. At this point, if a component isn't actively touching a bullet I'm pretty sure a 3d printed part is just as good as a COTS option. The everything-but-springs-and-barrels designs are interesting and from my experience quite reliable if properly finished afterwards. The versions that I've fired that had been specifically designed to use no traditional firearms parts and had their barrels "rifled" using electrolysis were functional if inaccurate and prone to jamming after a couple of shots since the magazine springs were either 3d printed coil-springs which wore out quickly or were made by hand as a test.Reply