Intel to Invest Up to $100 Billion in New Ohio Mega Site

Intel's next major manufacturing site to be in Ohio.

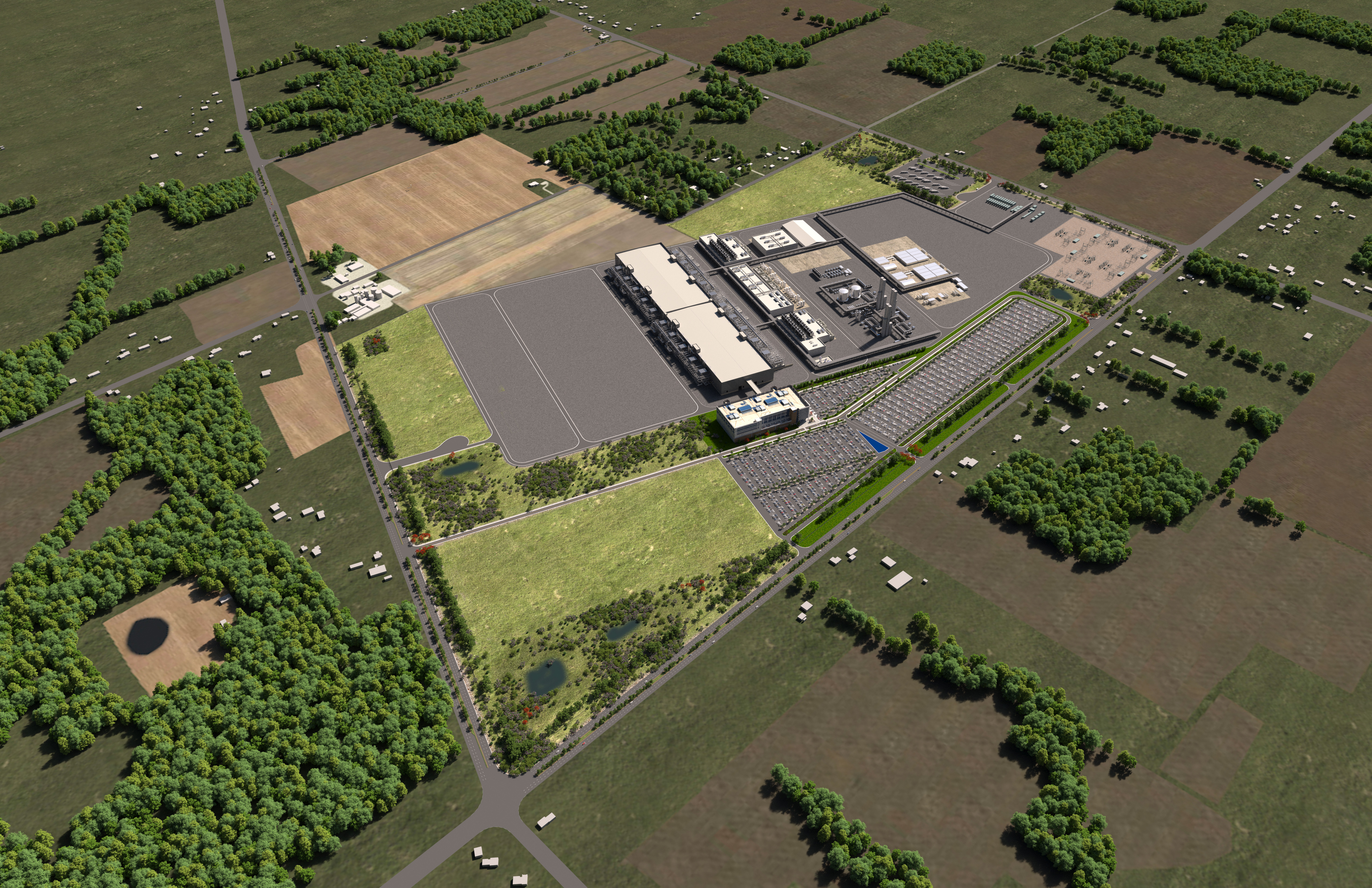

Intel have today said that it will build its next major manufacturing site in Ohio. The new 'mega site' will be similar to the company's other campuses in Arizona and Oregon, will house up to eight semiconductor production facilities and will cost up to $100 billion when fully built over the next decade. The construction will begin later this year and the first fab will go online in 2025. The initial investment will total $20 billion.

Intel does not disclose which fabrication technologies will be used by the new fabs, but judging by the timeline of the new site, we can expect the new fabs to be capable of making chips using Intel 25A and Intel 18A nodes (which will be among the most advanced manufacturing technologies in 2025), though we are speculating here. Manufacturing capacity of the new fabs is also unclear at this point since it will depend on actual production process, but it is evident that the new facility will be instrumental to support Intel’s IDM 2.0 strategy that involves internal manufacturing as well as contract production of chips for third parties.

"Intel's actions will help build a more resilient supply chain and ensure reliable access to advanced semiconductors for years to come," said Pat Gelsinger, CEO of Intel. "Intel is bringing leading capability and capacity back to the United States to strengthen the global semiconductor industry. These factories will create a new epicenter for advanced chipmaking in the U.S. that will bolster Intel's domestic lab-to-fab pipeline and strengthen Ohio’s leadership in research and high tech."

The new manufacturing site will be located near Columbus in Licking County and will span around 1,000 acres (4 square kilometres). Intel says that the new campus will be able to house up to eight semiconductor fabs as well as support operations and ecosystem partners. Initially Intel will invest $20 billion in two fabs at the site, but at full buildout and eight fabs constructed and equipped, the total investment in the site could reach a whopping $100 billion.

In fact, this new campus will be the largest private investment in Ohio ever and will be one of the making it one of the largest semiconductor manufacturing sites in the world. The initial phase of the project is expected to create 3,000 Intel jobs, 7,000 construction jobs, and tens of thousands of indirect local long-term jobs. In addition to investing billions in its new fabs, Intel will also spend $100 million over the next decade on partnerships with local educational organizations to help local research programs and educate local talent.

"A semiconductor factory is not like other factories," said Keyvan Esfarjani, Intel senior vice president of Manufacturing, Supply Chain and Operations. "Building this semiconductor mega-site is akin to building a small city, which brings forth a vibrant community of supporting services and suppliers. Ohio is an ideal location for Intel's U.S. expansion because of its access to top talent, robust existing infrastructure, and long history as a manufacturing powerhouse. The scope and pace of Intel's expansion in Ohio, however, will depend heavily on funding from the CHIPS Act."

Intel will immediately start planning for the first two fabs and intends to begin construction in late 2022. It typically takes about a year or more to construct main and supporting buildings and then a further year or more to equip semiconductor fabs. Keeping in mind that the new fabs in Ohio will extensively use extreme ultraviolet (EUV) lithography tools that are larger than modern deep ultraviolet (DUV) scanners and take more time to install, Intel expects that the new facility will become operational in 2025.

Stay On the Cutting Edge: Get the Tom's Hardware Newsletter

Get Tom's Hardware's best news and in-depth reviews, straight to your inbox.

Speaking of manufacturing equipment and materials used by the new manufacturing site, it is necessary to note that Intel’s partners plan to establish local presence to support the new operations. A number of Intel’s partners, including Air Products, Applied Materials, LAM Research and Ultra Clean Technology have indicated such plans.

Anton Shilov is a contributing writer at Tom’s Hardware. Over the past couple of decades, he has covered everything from CPUs and GPUs to supercomputers and from modern process technologies and latest fab tools to high-tech industry trends.