Lack of Engineers & Pandemic Slow Production Shift from China to Vietnam

COVID outbreak slows down migration of manufacturing to Vietnam.

Vietnam has long been considered the next major production base as companies want to diversify their supply chains to lower reliance on China. Yet, because of the ongoing SARS-CoV-2 outbreak in the region, tight border controls, and even local lockdowns, Apple, Google, Amazon, and their contract manufacturers are going to have problems with shifting their production to Vietnam this year. Yet, there is a bigger problem: not enough engineers in Vietnam.

Large companies like Apple and Asus as well as their production partners like Foxconn and Pegatron have been working on transferring production from China to Vietnam for some time now because the workforce in Tianxia has been getting more and more expensive.

The companies accelerated their efforts in 2018 after the U.S. began imposing punitive tariffs on devices made in China. In fact, both contract makers of electronics like Foxconn as well as original equipment manufacturers (OEMs) like Apple, Amazon, Dell, and Microsoft either established their presence in Vietnam, or expanded their operations in the country in the recent years, reports Nikkei.

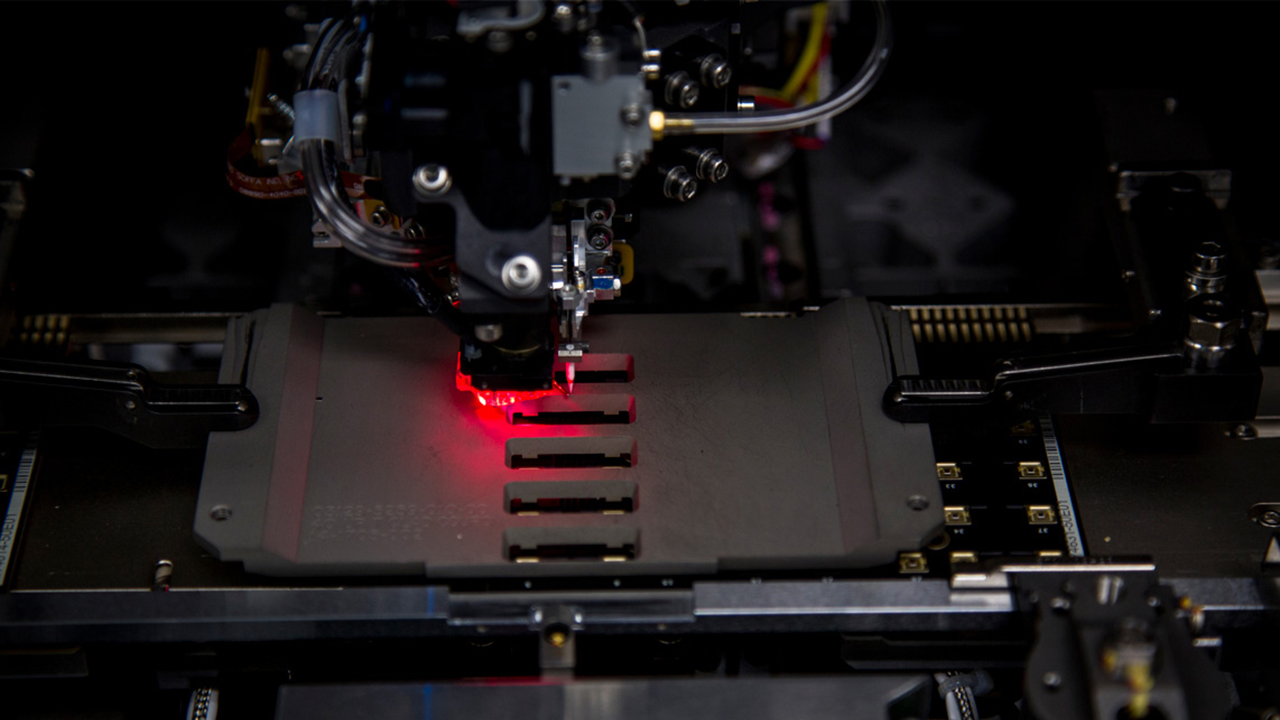

But local factories and supply chains require local engineers and training of local workers. Apparently, there are not enough homegrown engineers in Vietnam to build new supply chains or develop brand new products in collaboration with large suppliers. Furthermore, travel restrictions prevent engineers from other countries from coming to Vietnam to kick off new product lines. Essentially, Vietnam-based facilities can be used to make something that is already in mass production elsewhere, which makes Vietnam significantly less competitive.

"[Vietnam's] engineering workforce is still far from adequate," a supply chain executive serving Apple and Google said in an interview with Nikkei. "With all the travel restrictions, it's only feasible to make products in Vietnam that are already in mass production elsewhere, rather than starting production of upcoming products from scratch in the country."

Being one of the world's largest suppliers of electronics, Apple was among those at the forefront of moving some of its production to Vietnam. The company currently produces some of its AirPods-series headsets in the country, yet the vast majority of them are still made in China. The company hopes to make 20% of its AirPods in Vietnam eventually, yet the upcoming next-generation AirPods will start to be produced in China first.

Apple's plan also includes moving some iPad and MacBook production to Vietnam, but the supply chain is incomplete and there are not enough local engineers, a problem that has been further aggravated by the pandemic. The incomplete notebook manufacturing supply chain obviously affects not only Apple, but other laptop suppliers too.

Stay On the Cutting Edge: Get the Tom's Hardware Newsletter

Get Tom's Hardware's best news and in-depth reviews, straight to your inbox.

Amazon and Google have faced similar problems. Amazon has been facing delays with production of its devices like smart speakers in Vietnam due to SARS CoV-2 outbreak preventive measures since May. Google had to opt for China to make its Pixel 6 smartphones.

Shifting production of many products from China to Vietnam has proved to be s tough task so far. This is not exactly surprising since China has been building its 'world's factory' prowess for several decades now and it does not look like things are going to be easier for Vietnam.

Analysts believe that anti-pandemic measures imposed by the Vietnamese government are not going to last long because they are essentially killing the country's economy. Yet, gaining engineering talent and building up supply chains will take years, so suppliers will probably have to prepare for a long haul here.

Anton Shilov is a contributing writer at Tom’s Hardware. Over the past couple of decades, he has covered everything from CPUs and GPUs to supercomputers and from modern process technologies and latest fab tools to high-tech industry trends.

-

escksu Its not that easy to simply shift production to another country, esp. when vietnam is still lagging behind china in terms of things like infrastructure, labour and even suppliers.Reply

Look at the companies that shifted to plaes like india and vietnam, they still need to rely to china for parts and raw materials. -

Pytheus How about bringing production back to the US? There are plenty of engineers here who want good paying jobs and less reliance on China.Reply