WD Plots A Course To 40TB HDDs With MAMR

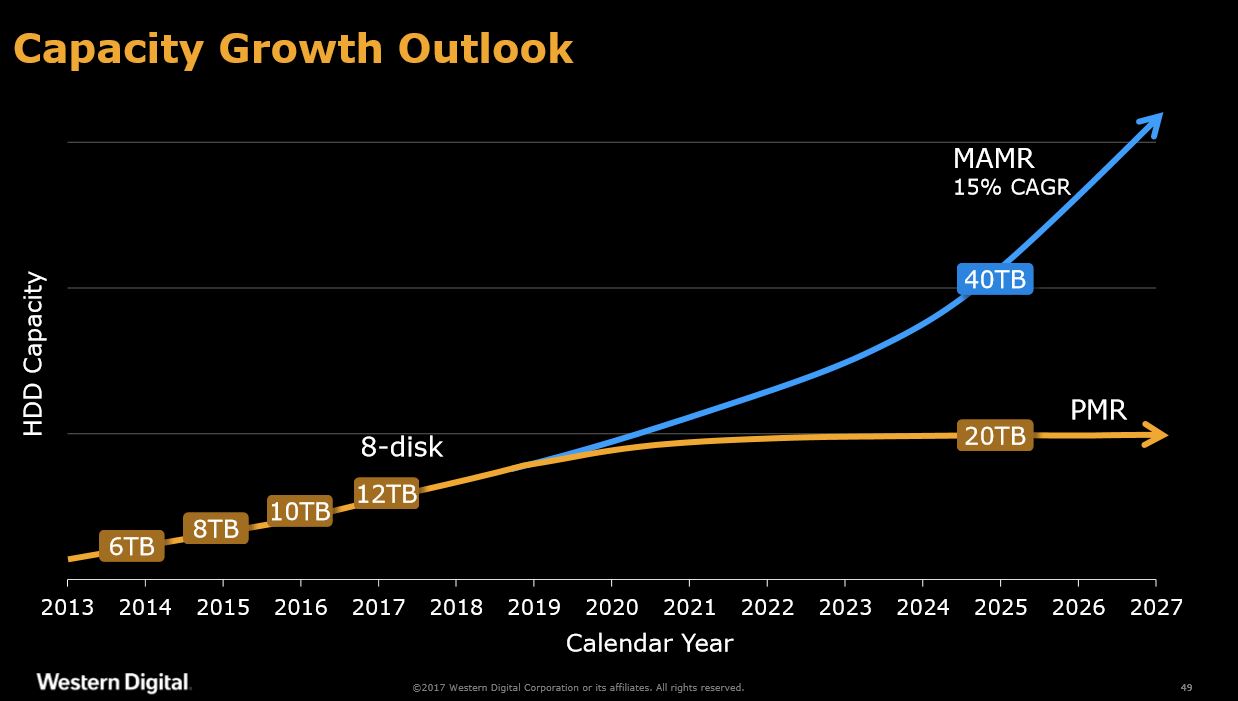

WD has selected MAMR (Microwave Assisted Magnetic Recording) as its new HDD recording technology, which the company claims can enable up to 40TB HDDs by 2025. WD's rapid transition to MAMR is somewhat surprising, but the technology has been in development for nearly a decade. It certainly stands in contrast to Seagate's plans for using the laser-assisted HAMR (Heat Assisted Magnetic Recording) as the route to higher storage density.

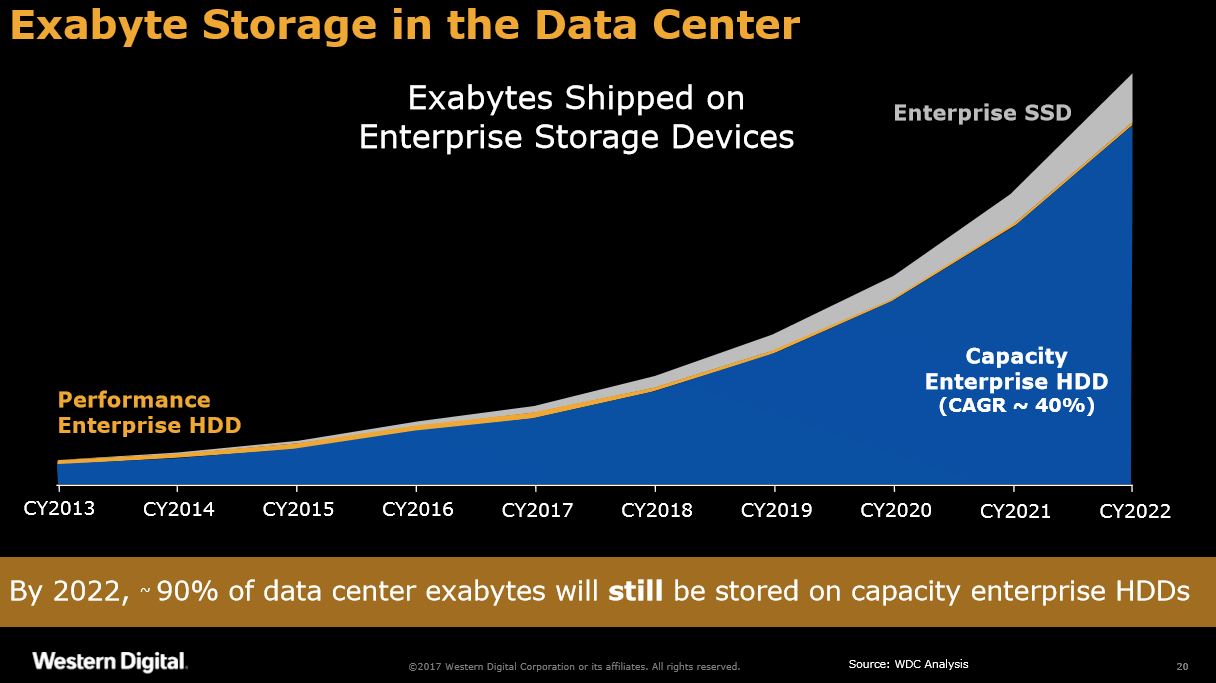

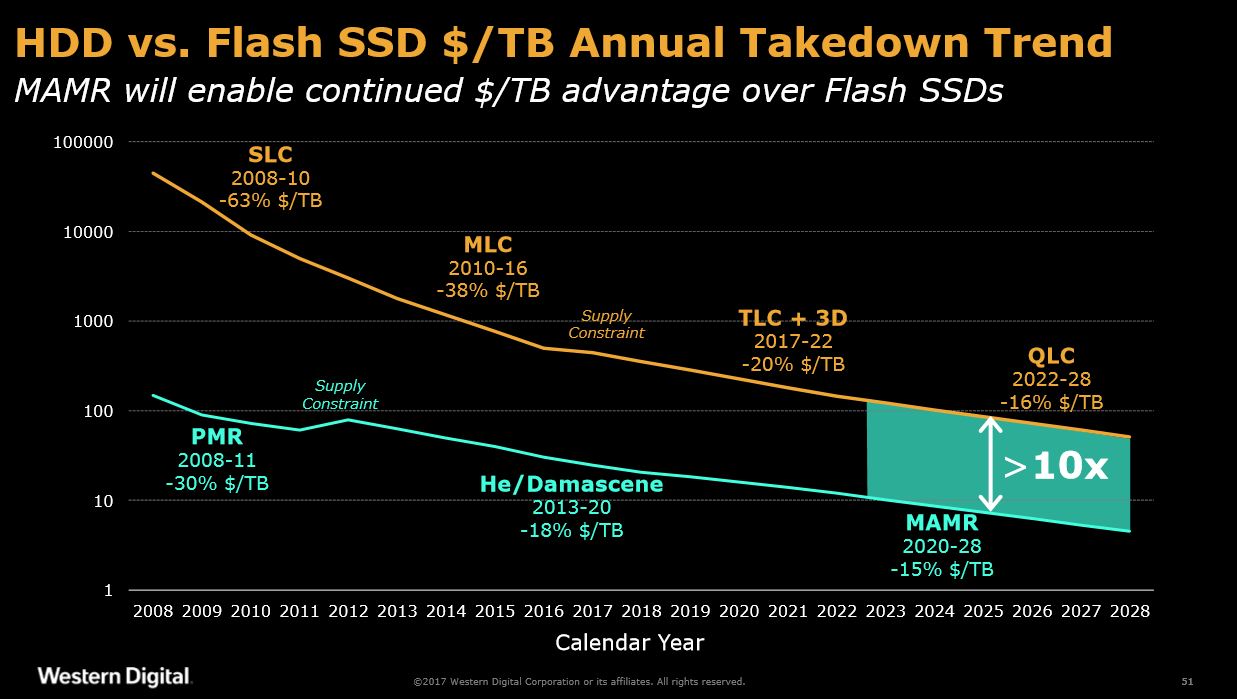

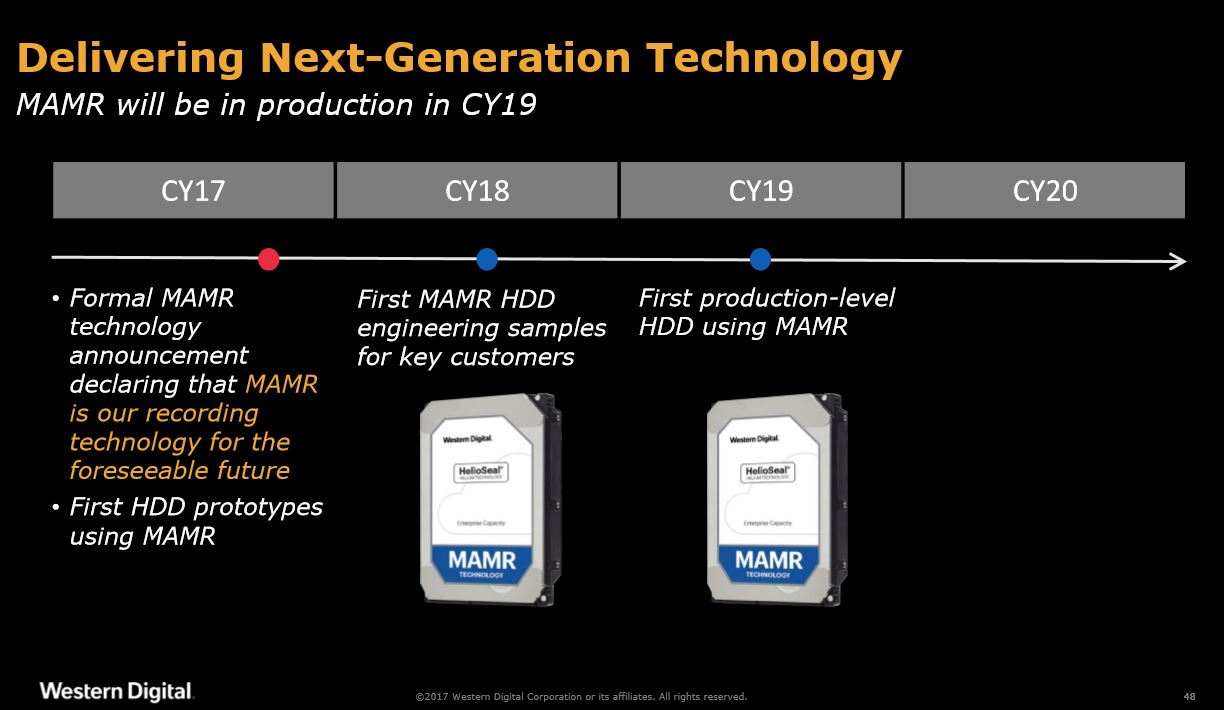

The transition to the new recording process isn’t immediate, but WD plans to have initial products shipping by 2019 and it had working demo models this week at its event in San Jose. The improved recording technology is needed to keep HDDs cost-competitive with the surging SSDs, but economics dictate that SSDs will never replace HDDs entirely, especially as the volume of data continues to grow exponentially; WD predicts that HDDs will account for ~90% of data center storage in 2020.

MAMR hard drives will debut in the data center and eventually filter down to NAS and video surveillance HDDs, but unfortunately, WD says that it will not bring the drives to the consumer market. The tactic makes some sense for WD, which also has a large presence in the SSD market due to its SanDisk acquisition.

HDDs are being replaced quickly in the client space. For instance, if we include data stored worldwide, such as in desktop PCs, laptops, and other devices, WD predicts that only 70% of data will be stored on HDDs in 2020. In either case, it is surprising that WD isn't planning on bringing higher-capacity MAMR drives to the desktop. We imagine WD will use the existing low-performance SMR (Shingled Magnetic Recording) to extend HDD density in the client market.

The Background

The HDD has evolved over the last 60 years into smaller devices as the industry shrunk the size of physical components to increase storage density. Shrinking the components, such as disks, heads, and the case, brought about huge improvements, but eventually the industry ran against the practical limits of reducing the size of the mechanical components.

Not that they didn’t try. The HDD industry spent tremendous time and treasure developing 1-inch HDDs (which debuted in 1999), envisioning that the tiny spinners would make their way into mobile products, such as the then-conceptual smartphone. That didn’t go well, thankfully, and the mobile industry transitioned to flash for those types of applications. In the meantime, the HDD vendors continued to improve recording technology.

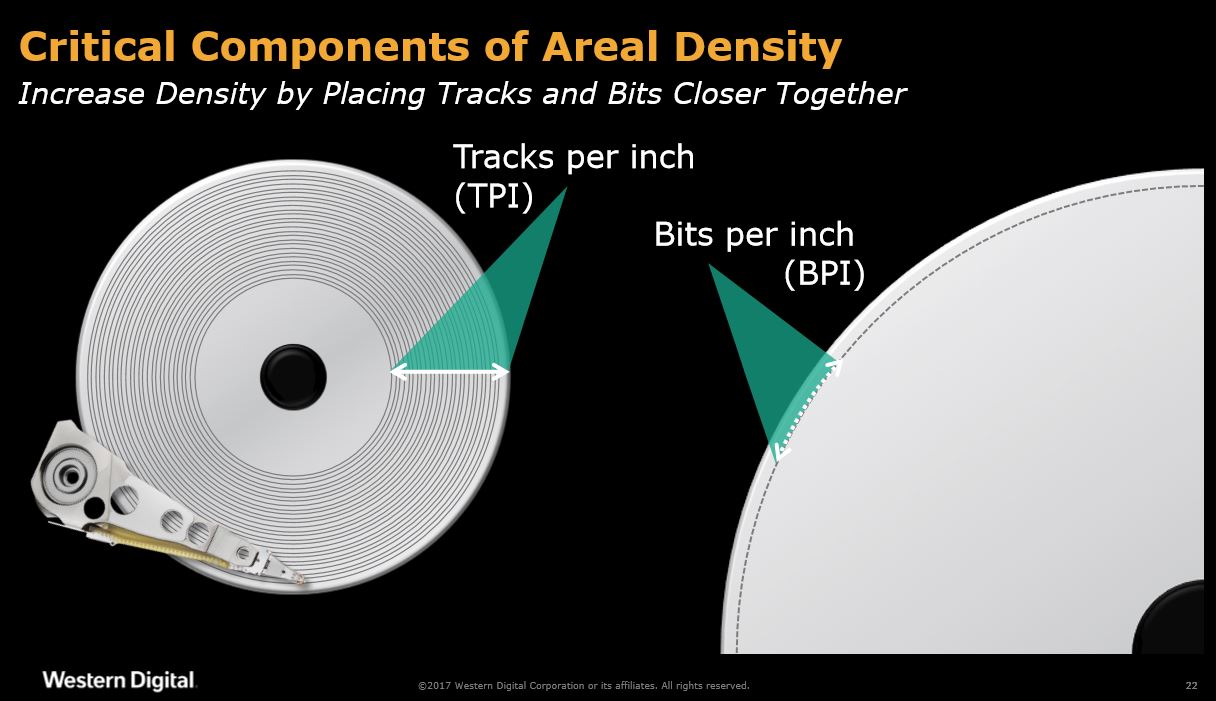

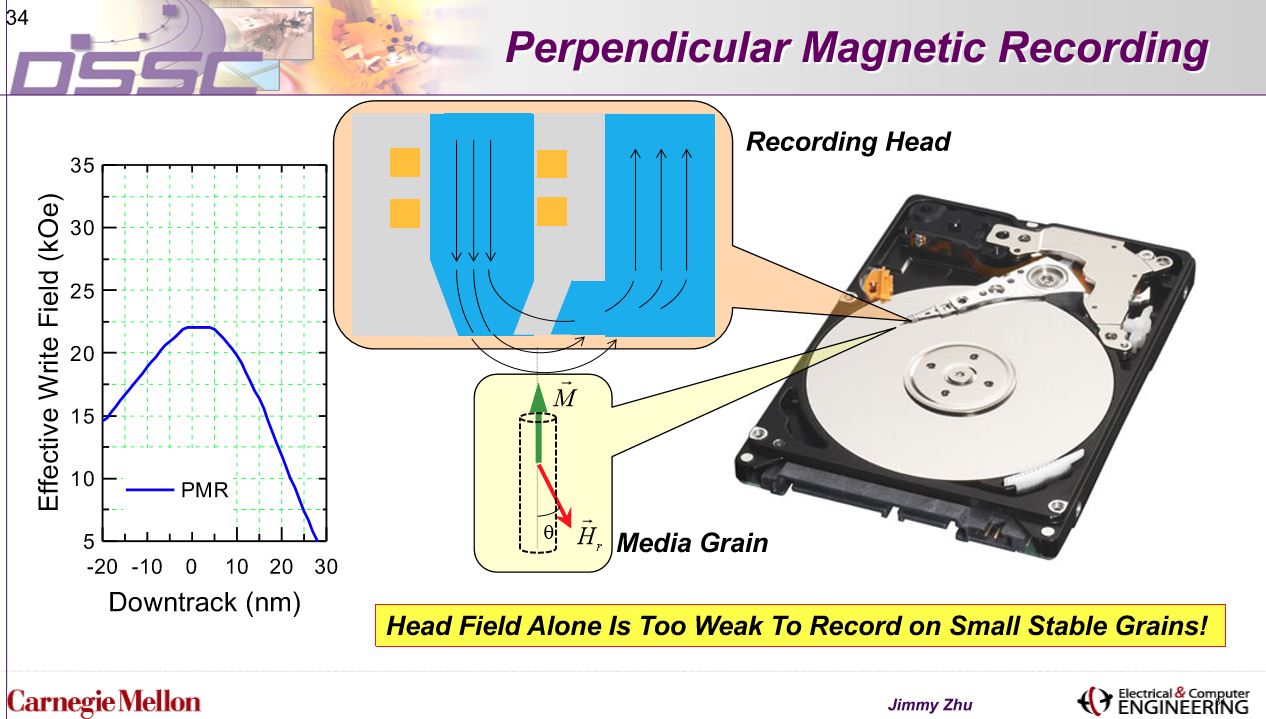

HDDs store data by magnetizing small bits aligned on a platter into tracks, and density improvements come by shrinking the TPI (Tracks Per Inch) and BPI (Bits Per Inch).

Get Tom's Hardware's best news and in-depth reviews, straight to your inbox.

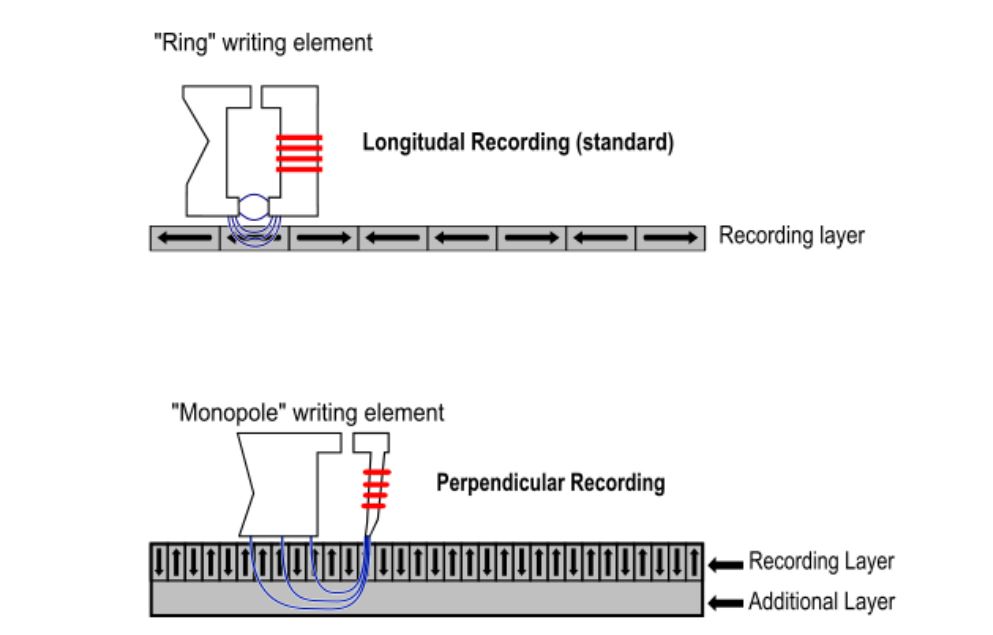

In the past, longitudinal recording was the go-to method for recording data on a hard drive. Longitudinal recording aligned the poles of each magnetic element (bit) horizontally.

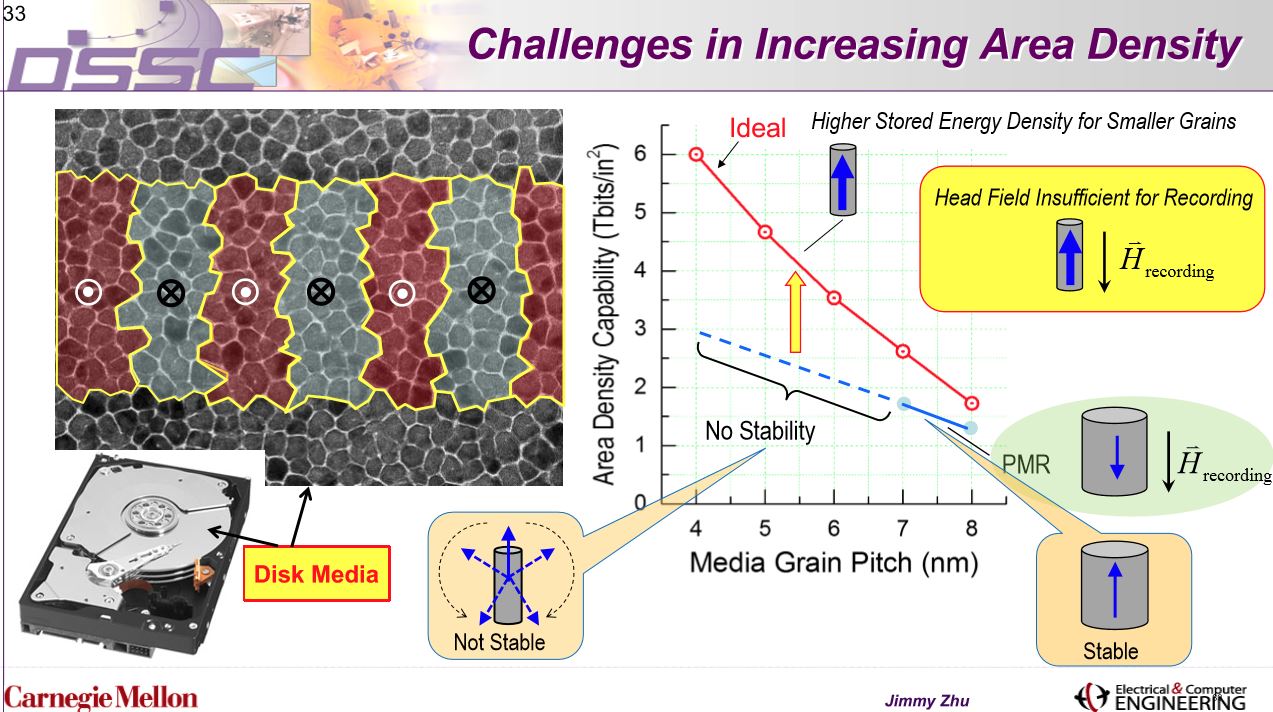

Shrinking the bits required "stronger" (higher coercivity) materials that could hold the magnetic charge within a smaller volume. Materials with higher coercivity are more thermally stable, which is important due to the superparamagnetic limit. This limit denotes that bits can be spontaneously de-magnetized by local thermal fluctuations if the magnetic regions of the bit are too small, resulting in data loss.

But the write heads of the era could not force enough energy into the smaller and stronger bits without disturbing surrounding bits. With PMR (Perpendicular Magnetic Recording), vertically aligning the poles allows the head to drive more directed energy into the material by routing the magnetic flux through an additional under-layer (see graphic). That enabled the use of stronger materials.

The Path Forward

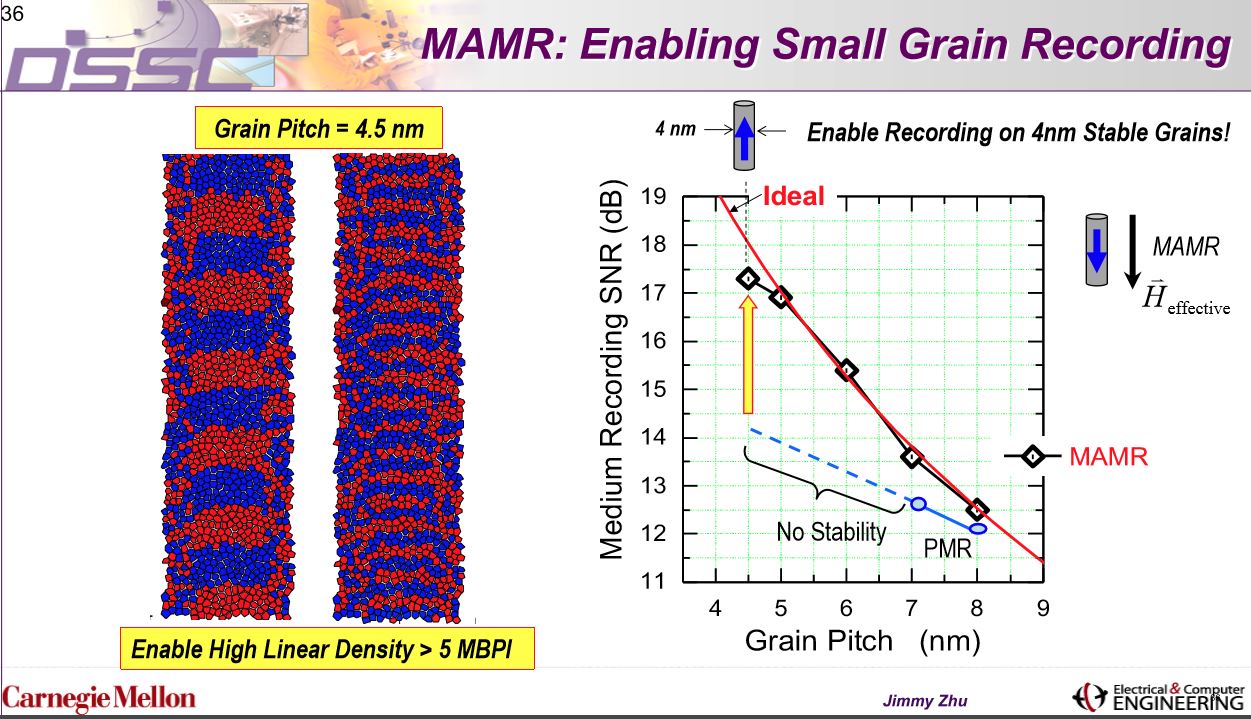

Current bits (also known as grains) are ~7nm, but shrinking them further requires even stronger materials. Today's head technology cannot force enough directed energy into the stronger material to "flip" the bits, especially with precision, so an energy-assist technology is needed to write data to the media successfully.

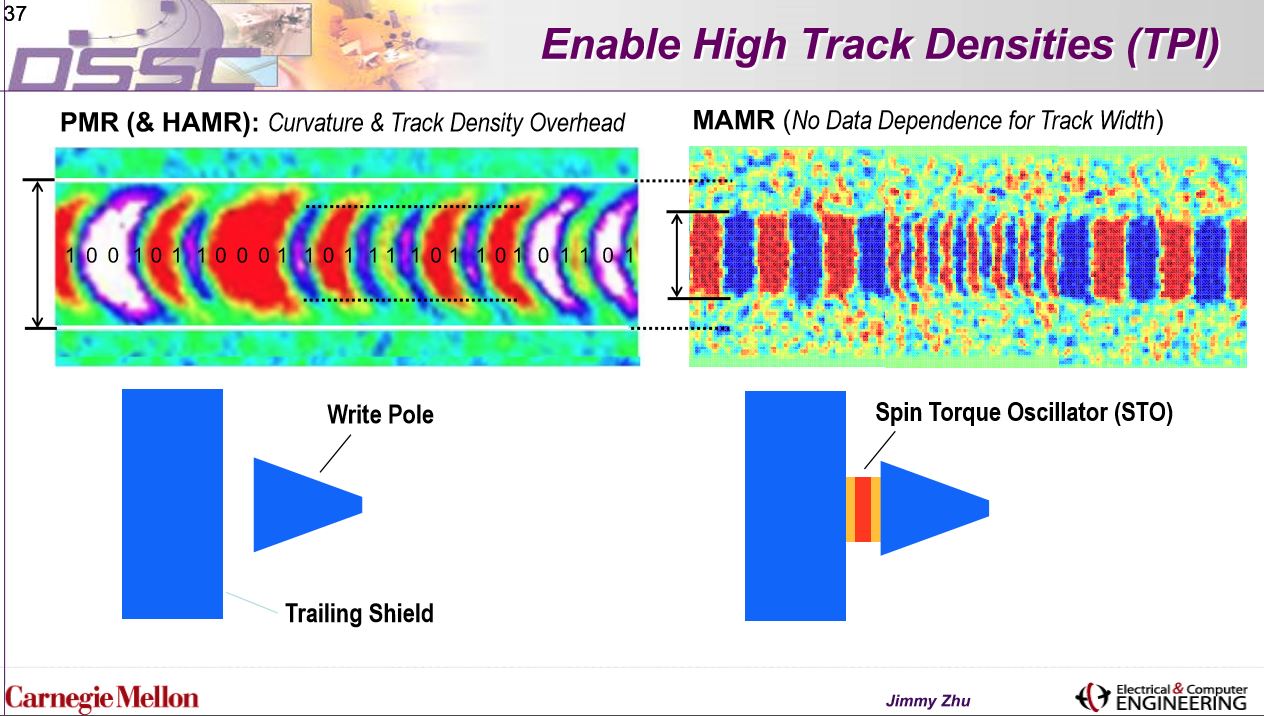

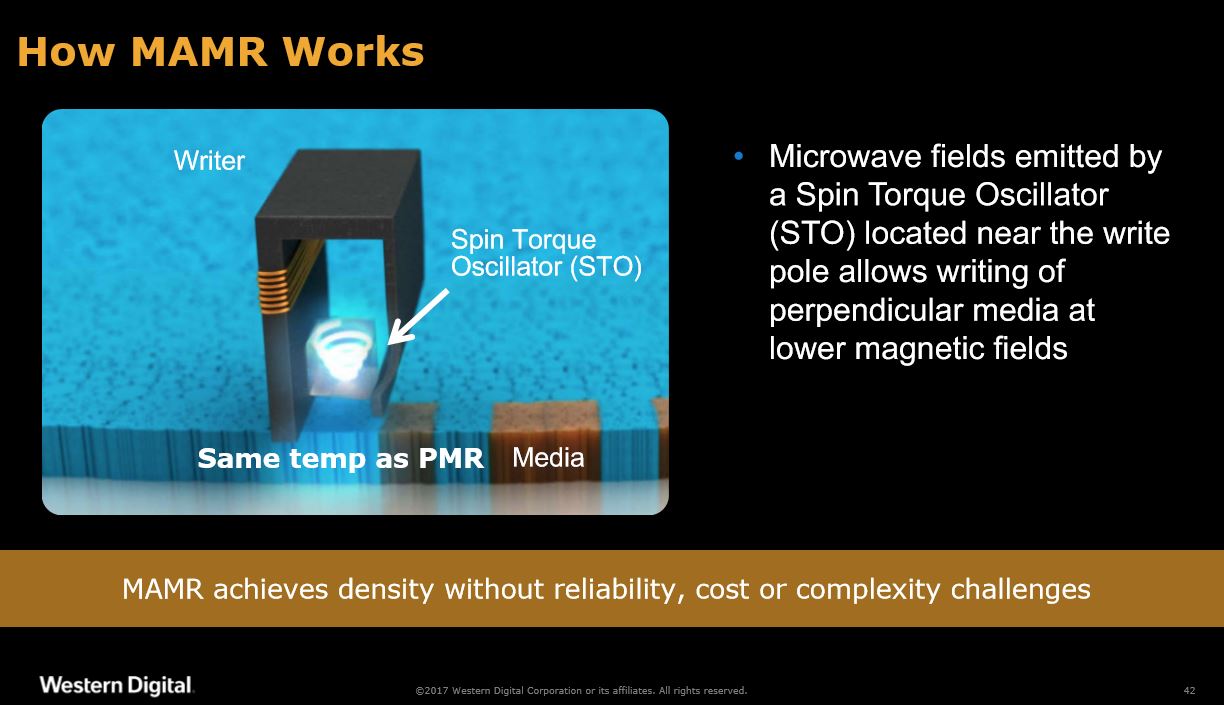

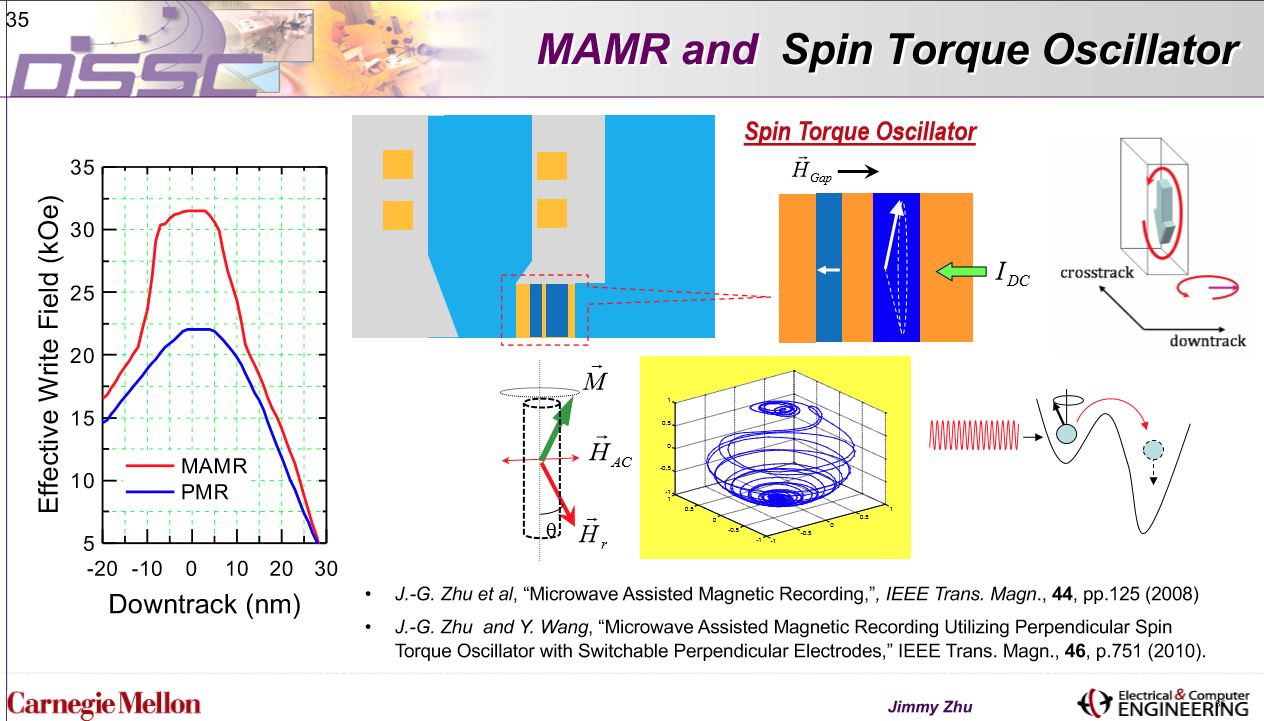

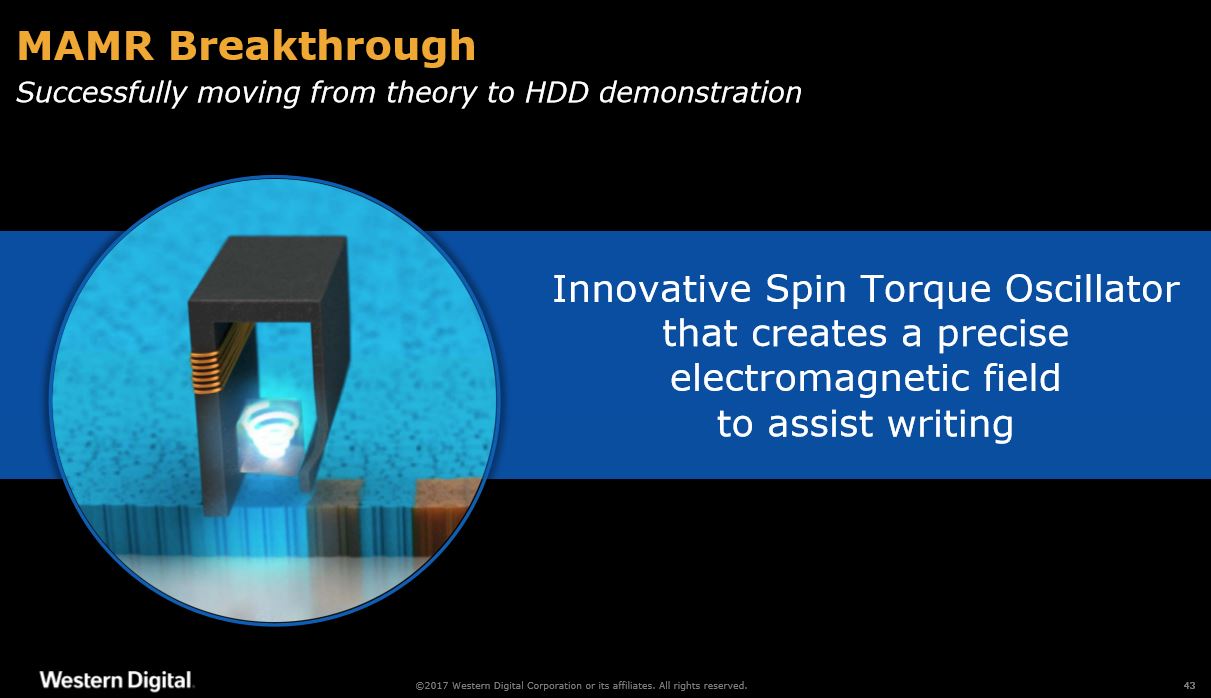

WD developed a Spin-Torque Oscillator (STO) to reduce the coercivity of the material so the head can impart enough energy into the bits to flip the magnetic state.

The STO resides in the center of the recording head and has 10nm multi-layer films consisting of magnetic and non-magnetic material. The head applies DC current to the STO, which in turn creates an electron spin. This rotation creates an electromagnetic field at a microwave frequency (20-40 GHz range), thus reducing the coercivity enough to pump sufficient energy into the bits to flip the magnetic charge. That will eventually allow the company to use 4.5nm grains as the technology evolves.

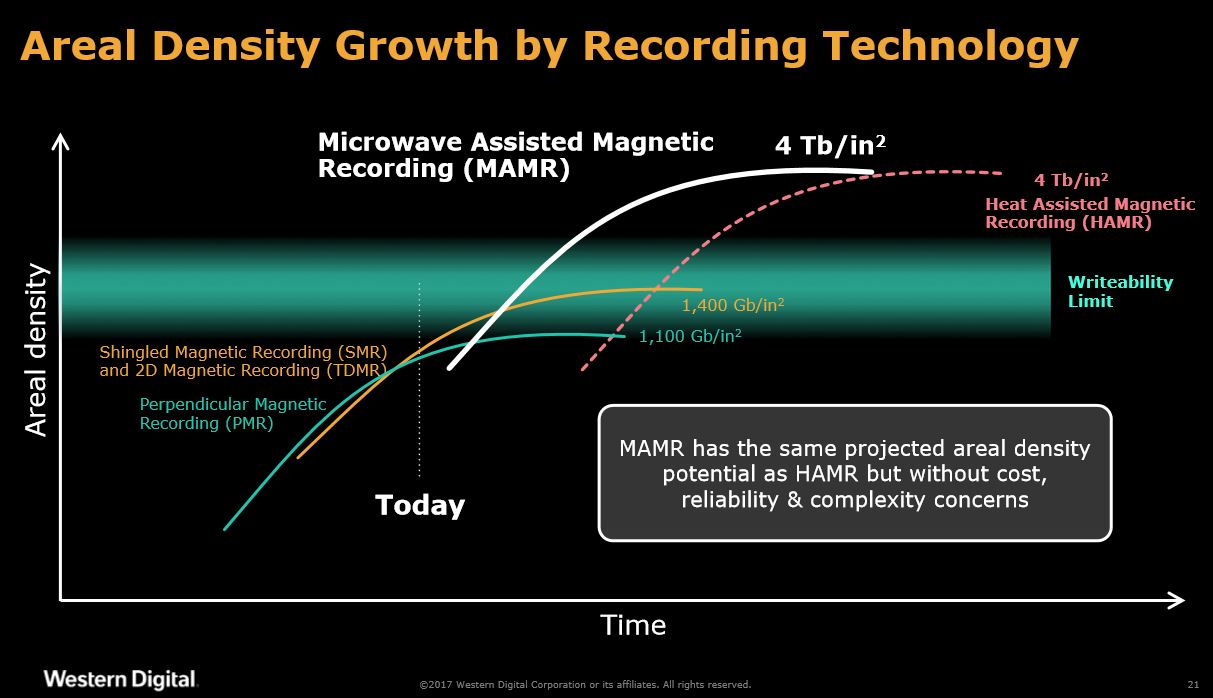

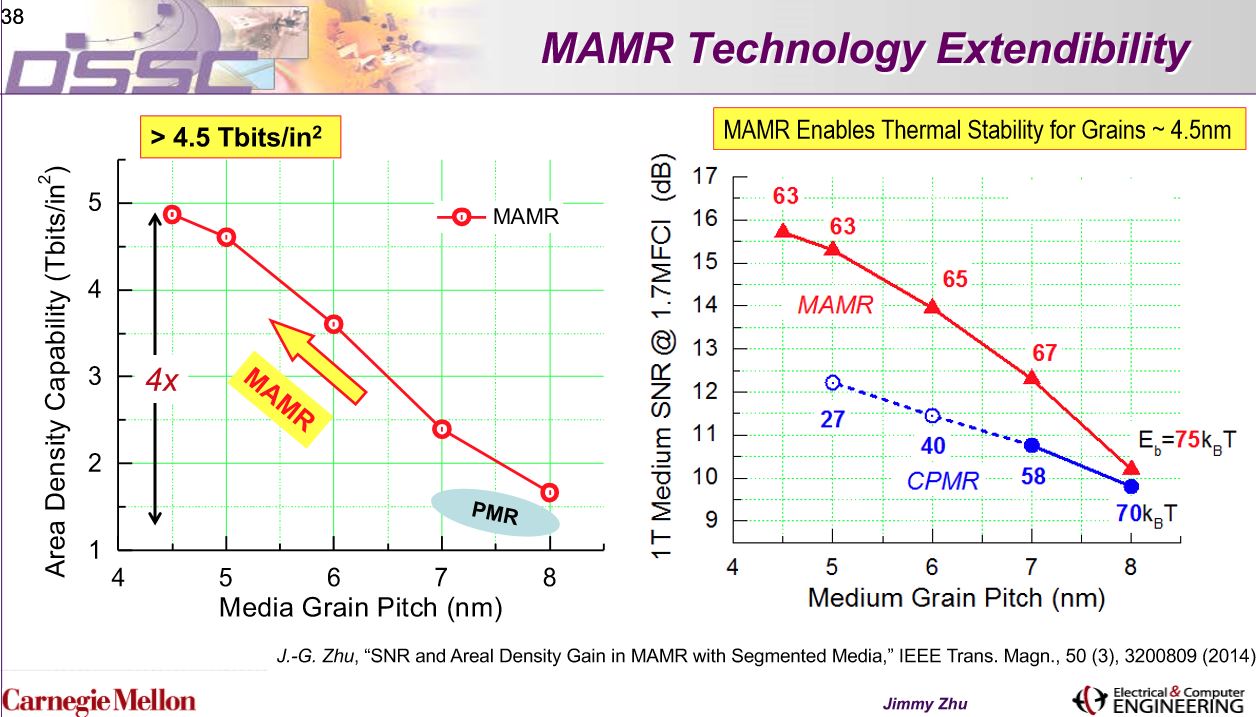

The new writing technique also improves media and track density by writing more well-defined data patterns than PMR or HAMR technologies. PMR's maximum density is currently predicted to be roughly 1.1 Gbit/inch², but combining it with other new technologies, such as SMR (Shingled Magnetic Recording), boosts the density potential up to 1.4 Gbit/inch2.

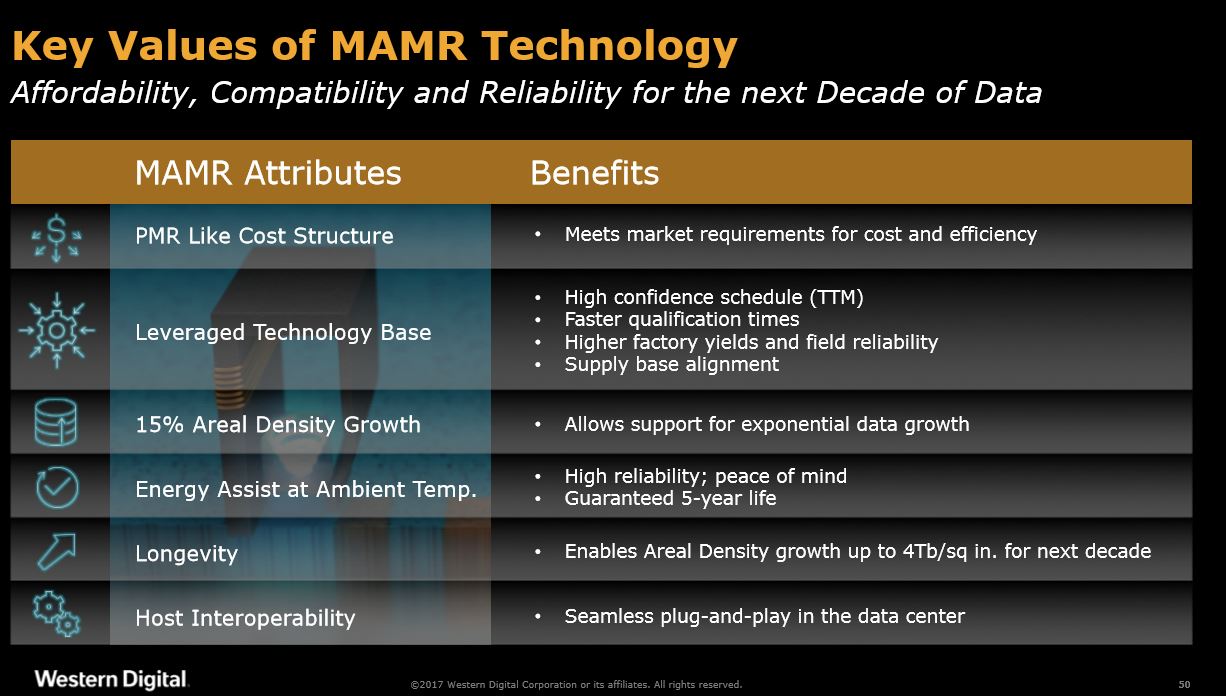

WD predicts that it can reach up to 4.5 Tbits/inch2 with MAMR. That enables a path forward to 40TB+ hard drives.

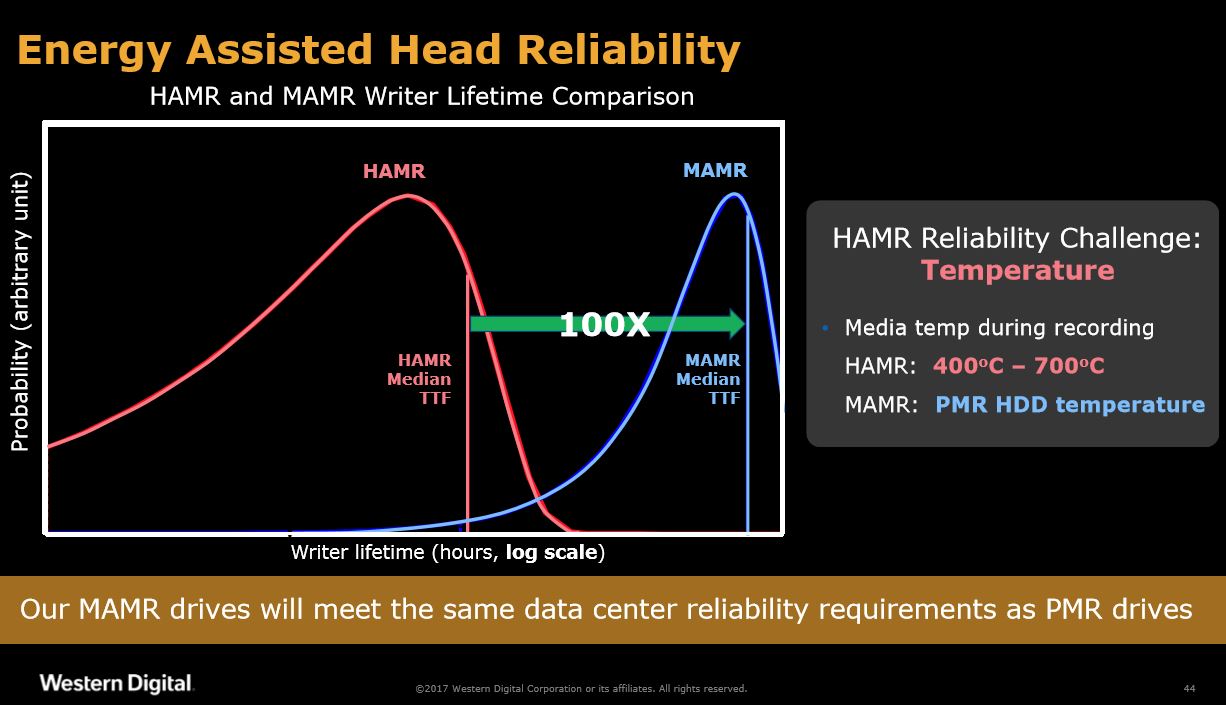

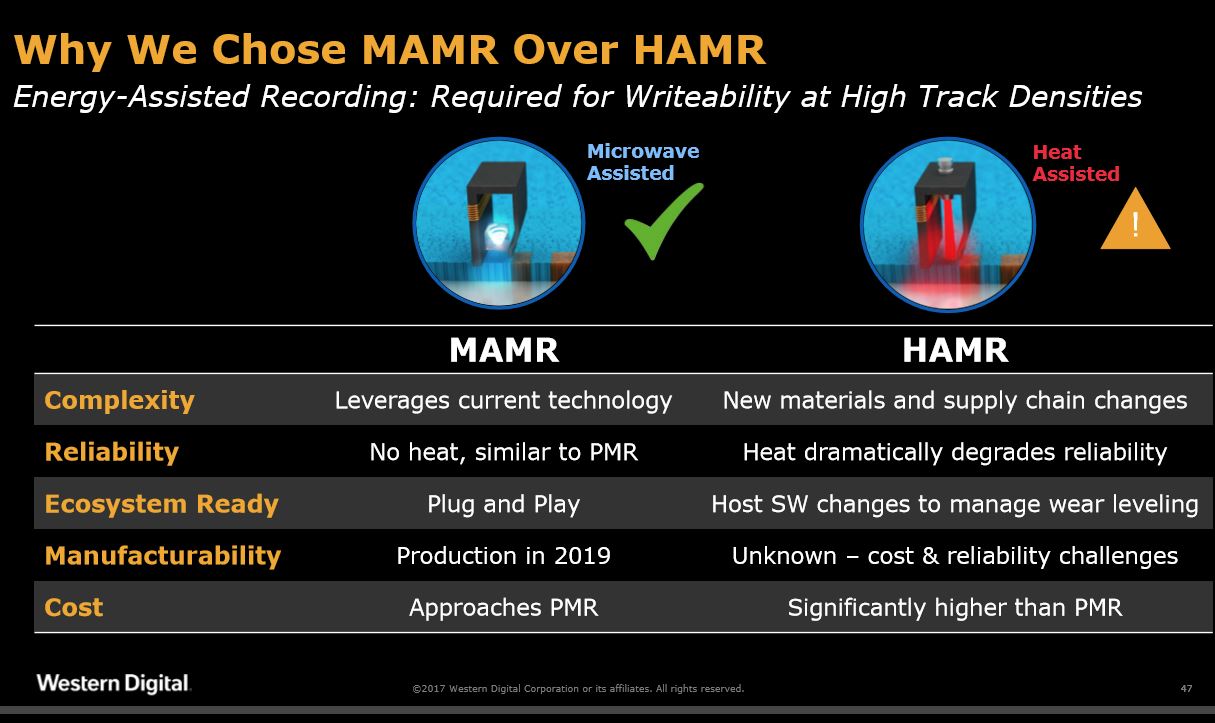

Of course, MAMR isn't the only option. Both WD and Seagate have researched HAMR (Heat Assisted Magnetic Recording) extensively, with the latter planning to deploy the technology in its future products. WD even had working HAMR demo drives at its event, but the technology is much more exotic.

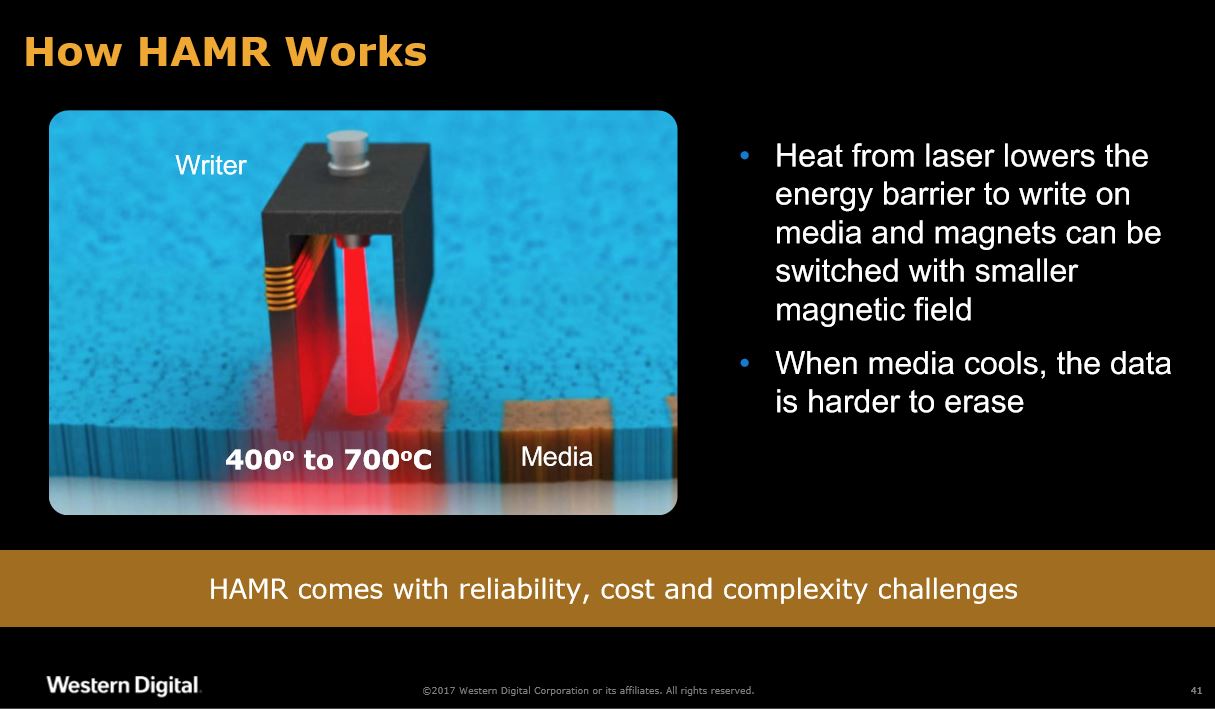

HAMR uses a small laser to heat a tiny portion of the platter (less than 20nm) to 400-700C. That lowers coercivity and allows the material to be magnetized. The rapid heating and cooling cycles present tremendous challenges that will require new platter and head materials, which increases cost. It also requires wear leveling to ensure uniform wear on the platters, which will require either software changes or embedded intelligence on the drive. In contrast, WD claims that MAMR will utilize existing technologies and materials with minimal changes, creating a plug-and-play solution.

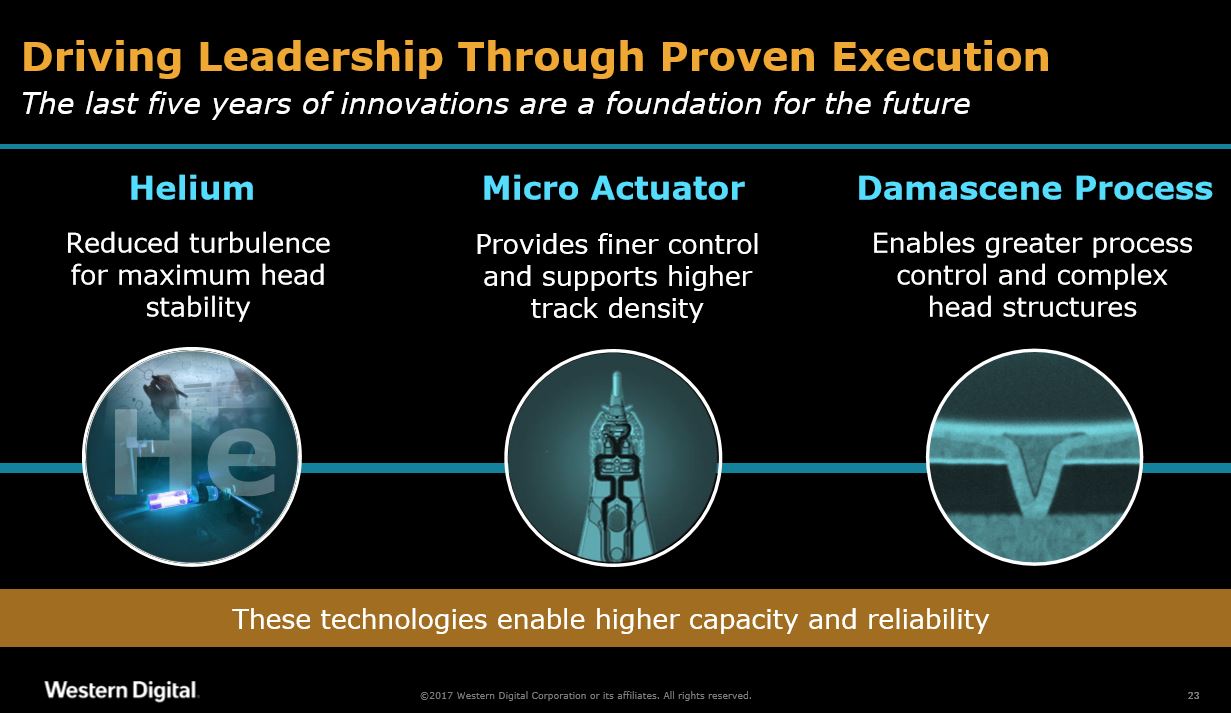

Even more promising, MAMR is interoperable with WD's other density-improving technologies, such as Damascene heads, helium, and SMR recording. WD led the industry transition to helium drives, and the advantages are a well-traveled subject.

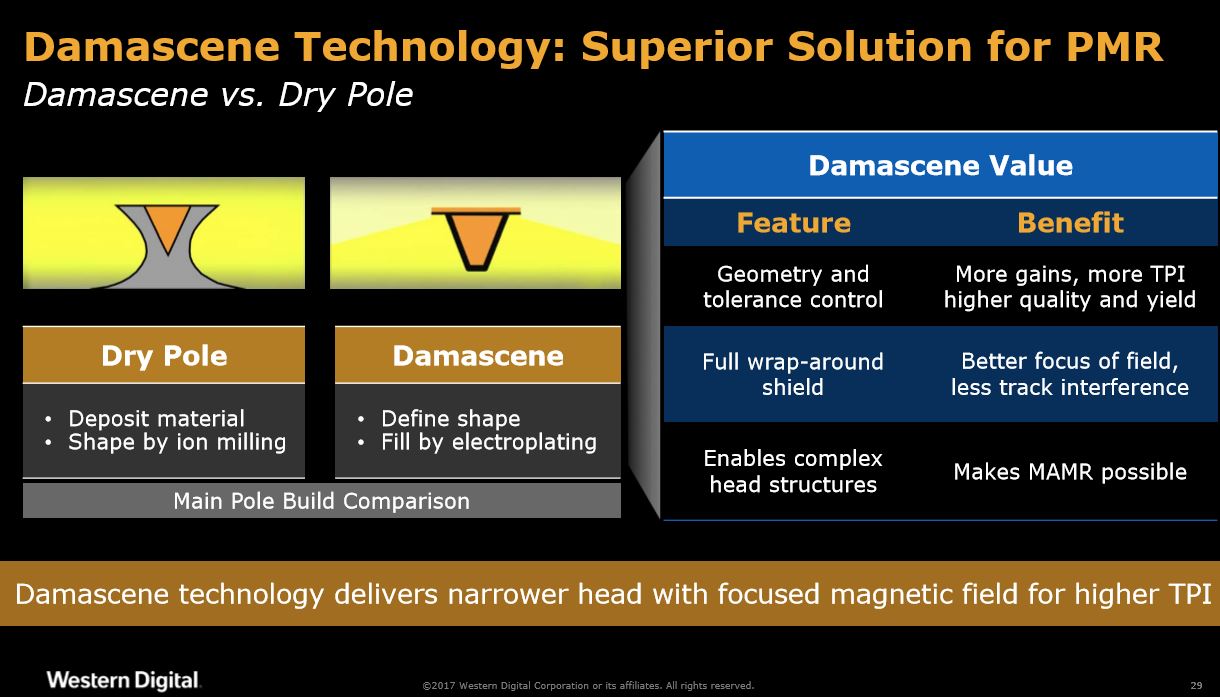

The company also pioneered Damascene head technology, which improves TPI due to its higher-precision writeability. Producing heads, like any other component, is subject to yield issues. Dry pole heads, the current technology of choice for other HDD vendors, are primarily manufactured by depositing materials and then applying an extensive multi-stage milling process that essentially carves the head out of a chunk of material. Creating a dry pole head requires roughly 1,300 process steps.

Damascene heads, though, are built by creating the head and then filling it with an electroplating process. That allows for more precisely defined features that boost performance and only add 300 steps to the process. By contrast, WD says it would require yet another 600 steps to create a HAMR-capable write head, which decreases yields. The improved MAMR head yields are one of the most crucial factors to reigning in cost--it requires roughly three months to create a head in a wafer fab. HAMR write heads also require exotic new features, such as lasers, that increase cost and reduce reliability.

WD also wraps the Damascene heads in a material that focuses the energy on its target, which reduces interference with adjacent tracks and bits. WD can create its own MAMR heads, and it owns the head technology, but it will not comment if it will also use third-party suppliers.

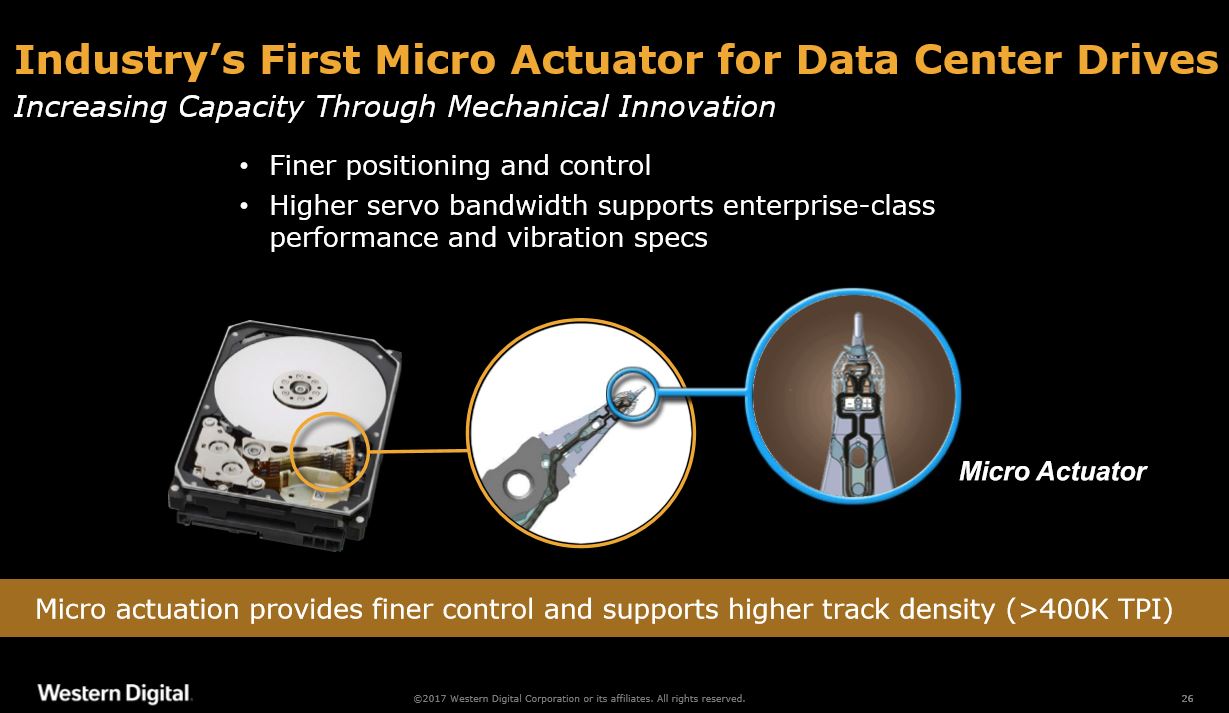

WD also improved its head positioning technology. Finer control of head positioning becomes paramount as track width decreases. The industry has progressed through several techniques, such as positioning the actuator at the end or middle of the arm, to increase precision. WD's new micro-actuator adds positioning capabilities at the head itself, thus improving accuracy. WD can also use the heads in tandem with other promising technologies, such as TDMR, which uses multiple read heads to boost the readability of thinner data tracks. WD's current approach doesn't require multiple heads, but it could be useful as the technology scales to even smaller tracks in the future.

WD contends that MAMR will provide a 4x density improvement over PMR. WD's MAMR could provide a cost and time-to-market advantage over Seagate's HAMR approach, but much of that rests on Seagate's production capabilities. Seagate has committed to releasing HAMR drives, but the company has constantly pushed the timeline further into the future.

Final Thoughts

Overall, WD's MAMR technology promises to bring similar performance to typical PMR drives, albeit with small improvements due to enhanced density. It also doesn't require any changes to the existing storage hierarchy, including hardware and software, or any radical new materials that would present a supply chain issue. Most importantly, the company claims its MAMR offers similar reliability characteristics, such as a 550TB/year workload tolerance and 2.5 million hour MTBF within normal operating conditions, and leverages several of its proven technologies.

But as important as reliability is, cost is a crucial factor. WD claims that MAMR drives will feature roughly the same price-per-TB as PMR HDDs, and cost will decline as the technology matures. That's a critical factor to ensuring the drives are palatable to the high-volume data center/hyperscale target market, but it also ensures that HDDs will remain cost-competitive with SSDs for the foreseeable future, even in the face of ultra-cheap QLC NAND technology.

The drives won't make it to market until 2019, but all new WD data center drives will feature the technology. That means the company will effectively retire PMR for newer high-capacity data center drives. That says a lot about the company's confidence in MAMR and its production scalability. WD claims that production will begin at high volumes immediately upon launch instead of the staggered rollouts we are accustomed to. The company isn't telling us what capacity the leading models will ship in, but given the capabilities of the new technology, WD could quickly distance itself from competitors.

Paul Alcorn is the Editor-in-Chief for Tom's Hardware US. He also writes news and reviews on CPUs, storage, and enterprise hardware.

-

jossrik Reply20270334 said:WD has selected MAMR (Microwave Assisted Magnetic Recording) as its new HDD recording technology, which the company claims can enable up to 40TB HDDs by 2025.

WD Plots A Course To 40TB HDDs With MAMR : Read more

I'm still waiting for inexpensive 5Tb drives or such, and by that I mean we've had 75$ 3Tb drives for years and years, higher density, the price goes up and up. Ya, they do sell 12Tb drives, but you pay so much more for them that you might as well get a NAS and fill it with cheaper drives, or even cheaper, build a NAS. When will these awesome drives trickle down for mainstream use? -

bit_user It amazes me to ponder the level of precision in modern HDDs. I wonder if there are any other mass-produced mechanical devices with such precision.Reply

What's more, in 5 years of continuous operation (some warranties are that long), a 7.2 kRPM drive will spin almost 19 billion revolutions, and still have sufficiently low jitter that you can seek to within nanometers of any location on disk, in about 1/100th of a second or less. These are true marvels of modern science, engineering, and manufacturing, IMO. And yet, they're frequently derided as spinning rust. -

pjmelect There is no way that I would buy a drive that uses Shingled Magnetic Recording, I imagine that these drives will be fitted in cheap laptops built down to a price for unsuspecting buyers. The performance of these drives will be appalling.Reply -

bit_user Reply

They're currently targeted mostly at backup and cold storage. They're actually fine, as long as your writes are sequentially.20270651 said:There is no way that I would buy a drive that uses Shingled Magnetic Recording, I imagine that these drives will be fitted in cheap laptops built down to a price for unsuspecting buyers. The performance of these drives will be appalling.

If you try to use them as a general-purpose HDD, then you're correct that their appalling random write performance is too big of a liability.

For those who don't know, these drives have (typically 15 to 40 MB) zones that overlap and therefore must be written only in their entirety. If you want to write only a subset of a zone, then you must read-modify-write the whole thing. This is the main reason for their poor random write performance. And as the areal density increases, zones sizes will only go up (it varies from one drive to another).

-

cryoburner ReplyThe company isn't telling us what capacity the leading models will ship in, but given the capabilities of the new technology, WD could quickly distance itself from competitors.

You should be able to estimate that base on the "Capacity Growth Outlook" graph they provided, which shows PMR density leveling off over the next few years, and maximum MAMR capacities continuing to grow at roughly 2TB per year in their place. That would imply that there will be no major surge in capacity, but that MAMR will simply take over as gains with PMR slow. Their graph doesn't show MAMR hitting the 20GB mark until at least 2020, so if the first MAMR drives appear prior to that, we can assume their maximum capacity will likely be lower, maybe 16-18TB, and probably at a price of over $500, like their current 12TB drives.

I would also take their suggestion that this will enable them to produce 40TB drives by 2025 with a grain of salt. That same graph suspiciously needs to curve sharply upward during the 2020s to get there. It's likely just a suggestion meant to instill confidence in investors, and they can be reasonably sure that no one will hold them to it 8 years down the line. I also have doubts that they will continue to maintain the same lead in terms of cost over flash storage over that time span, especially when you consider that for high-capacity bulk data storage, you don't need the same level of performance or write cycles found in most existing SSDs. With the slow rate of advancement in hard drive densities, it seems quite unlikely that they will hold a 10x cost advantage over flash storage in 2025, and SSDs designed specifically for bulk storage might potentially even make them obsolete by that point.

One thing they could potentially do is make them into hybrid drives with a suitably large flash buffer built in. So, for example, the drive could have 128GB of flash memory, which could be written to quickly, and then the drive could write that data to the platters in the background, whenever it's convenient. Files with frequent random accesses could remain exclusively in the flash memory. So you could have your high capacity multi-terabyte drive, but you would also have much faster performance than a typical drive under most common usage scenarios.20270651 said:There is no way that I would buy a drive that uses Shingled Magnetic Recording, I imagine that these drives will be fitted in cheap laptops built down to a price for unsuspecting buyers. The performance of these drives will be appalling. -

AnimeMania Reply20270544 said:It amazes me to ponder the level of precision in modern HDDs. I wonder if there are any other mass-produced mechanical devices with such precision.

What's more, in 5 years of continuous operation (some warranties are that long), a 7.2 kRPM drive will spin almost 19 billion revolutions, and still have sufficiently low jitter that you can seek to within nanometers of any location on disk, in about 1/100th of a second or less. These are true marvels of modern science, engineering, and manufacturing, IMO. And yet, they're frequently derided as spinning rust.

They could take some of that tech and reinvent the inkjet and 3D printer heads. -

JonDol @AnimeMania: I'd be happy with less than that, like improving the life time... I used my previous printer mainly for scanning things about less than once a week and it died after 7 years. I think that it is too short considering my usage, compared to other mechanical HDDs I have that still work after 14 years and which were used for long months in 24h/7 running machines.Reply

Other than that, there are long years since the storage area (whether mechanical or flash) is the one carrying the most innovations year over year (of all the parts of a computer) so I'm a bit less amazed, I think, than our colleague bit_user, about these products reliability. A completely different approach vs the planned obsolescence we usually see with the printers... Add to that the impossibility of using non manufacturer (read low cost) ink cartridges and we'll have a very happy picture.