The Chinese-exclusive GeForce RTX 5090D, which has the potential to rival the best graphics cards, is the latest Blackwell graphics card to be affected by issues related to 16-pin (12VHPWR) power connector meltdowns. Uniko's Hardware has unearthed two recent instances of the GeForce RTX 5090D with melted 16-pin power connectors, reported on the Baidu Tieba forums.

With the introduction of the revised 12V-2x6 power connector, we had hoped the meltdown issue was behind us. However, doubt still remains since every once in a while, we see a user report pop up on the Internet. While reports of 16-pin power meltdowns have become less frequent, they haven't disappeared entirely. As we've seen, there is no specific incubation period for the meltdowns; it can occur a few days or weeks after the build, or sometimes even years later.

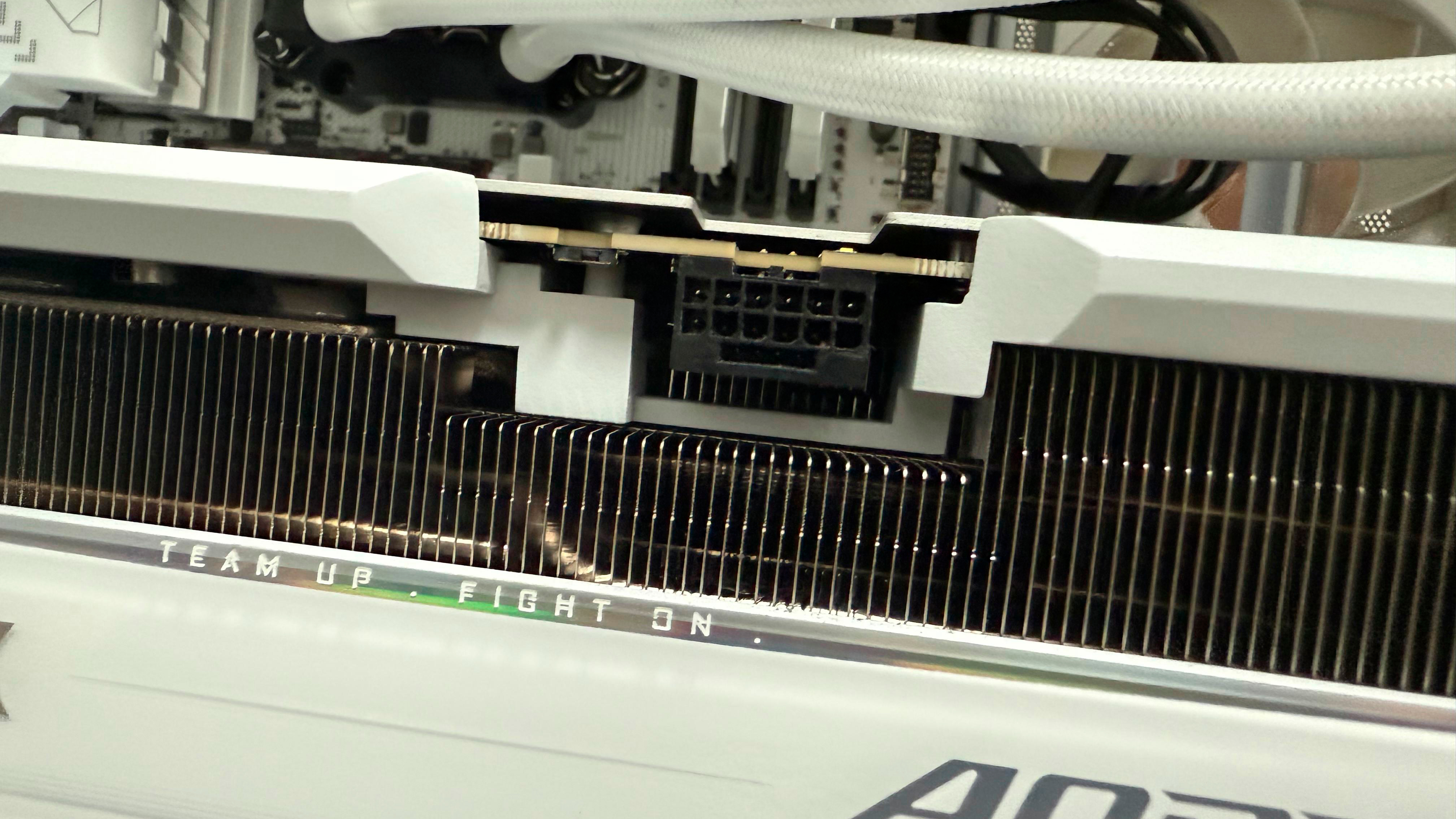

A Baidu Tieba user reported that his Aorus GeForce RTX 5090D Master Ice functioned well for two months before the 16-pin power connector melted. He reportedly used the native 16-pin power cable supplied with his Segotep KL-1250G power supply. Segotep, a well-known Chinese manufacturer, has over two decades of experience under its belt. The KL-1250G is an ATX 3.0 power supply rated at 1,250W and certified for 80 Plus Gold efficiency.

Another forum user recounted his unfortunate experience with his Gainward GeForce RTX 5090D graphics card and an Asus ROG Loki power supply. He did not specify the exact model he possessed but merely stated that he utilized the native 16-pin power cable. In his situation, the 16-pin power connector melted on both the graphics card and the power supply side.

In the first case, forum members criticized the user's Segotep KL-1250G power supply. One participant mentioned that this power supply was frequently associated with the previous GeForce RTX 4090 meltdowns. Although Segotep is an established name in the Chinese market, we cannot vouch for the quality of its products. In the second case, however, the user deployed an Asus ROG Loki unit, so its quality was not in doubt.

There have been many theories about what's causing the 16-pin power connector meltdowns on Nvidia's GeForce RTX 40-series (codenamed Ada Lovelace) and GeForce RTX 50-series (codenamed Blackwell) graphics cards. However, one of the most prominent theories is that Nvidia's revised PCB design for Ada Lovelace and Blackwell has effectively eliminated load sensing and balancing. On the contrary, the older GeForce RTX 30-series (codenamed Ampere) graphics cards had this feature. For this reason, the GeForce RTX 3090 Ti, despite having the same 450W TDP as the GeForce RTX 4090, never suffered from melting connectors.

Follow Tom's Hardware on Google News to get our up-to-date news, analysis, and reviews in your feeds. Make sure to click the Follow button.

Get Tom's Hardware's best news and in-depth reviews, straight to your inbox.

Zhiye Liu is a news editor and memory reviewer at Tom’s Hardware. Although he loves everything that’s hardware, he has a soft spot for CPUs, GPUs, and RAM.

-

spongiemaster ReplyIs any GPU with the 16-pin power connector safe?

Yes, all the professional GPU's from Nvidia and Intel that use this connector. AMD's just announced Pro GPU's will be using this connector as well. -

chaz_music Here is a copy paste from my prior comments in this:Reply

I have commented on this so many times:

If they are Hell bent on sticking with this configuration on the GPUs, they should be using interleaved PWM switching stages, with one power stage used per pin. In other words, do not tie the PSU pins together in parallel: Treat each pin as its own supply with its own Buck converter causing equal current draw. This allows the PWM controller to force each pin to draw a balanced load and not rely on uncontrolled parallel path resistances.

Since they are probably using interleaved Buck converters anyway for this high of a power rating, this would not incur much of a price increase for the GPU. It might require some added input filter capacitance on each Buck converter due to conducted EMI back toward the main PSU. The nutting thing here is that these interleaved Buck converters are having to create equal currents in their power stages inherently. But their inputs are getting tied together and accepting the input power from a paralleled wiring system.

This is why companies should have a seasoned consultant come in and review their designs. In this case, a power electronics guy.

Mercy, this is such as obvious and simple fix. And I mean bonehead simple.

And some suggestions to help people with these in the meantime (from a previous post of mine):

1. Do not use cabling that has a wiring loom wrapped around it, which acts as to reduce and constrict the airflow. The connector datasheets are expecting decent wire cooling to draw heat away from the connector housing at rated current. So no "pretty" nylon shroud covering the wiring. This allows for reasonable convection cooling of the wire. If this loom exists, remove it and allow the wire insulation to convection cool better. If you really want the wiring looms, you should consider heavy current/power derating for safety (like only below ~300W).

2. The wire is expected to act as a heatsink for the connector pins and sockets. Again this is simple physics used in ALL connector systems. The pin and socket contact points are tiny and much smaller than the wire cross-sectional area bring current to the pins & sockets. For this reason, suppliers should find a way to use larger wire than is presently being used. Even tool up a larger pin that fits the housing.

3. Since the pin and socket contact points have gone through oxidation and corrosion before you even install them, you should plug and unplug them several time to knock this oxidation off. Don't get excessive with it because you don't want to create fretting failure by scrapping off too much tin plating. About 3-5 time is great. One post I read stated that these pins are only rated for 50 insertions for their entire lifetime. Make sure the last insertion is seated well. Think about how long the GPU took to get to you, sat in a transport ship with high humidity to get to you, was even assembled in a factory with high humidity when it was soldered together.

4. You want to get the heat out of the cabling ends. So mount a fast fan by the GPU connector, as well as at the PSU connector. The imbalance can be caused by both ends of the cable! The fans should be mounted close by the connectors so that the airflow is "impingement".

I hope these suggestions help people while the industry addresses these shortcomings. -

ezst036 Reply

Yes.Admin said:Is any GPU with the 16-pin power connector safe?

Nvidia properly shunted its 30x0 series cards. I still have not yet seen a melting connector with them. One probably does exist, maybe, to be fair.

The Asus 4090 Matrix are properly shunted. Not seen those have a melting connector either. The Asus 5090 Astral is also properly shunted to prevent a melting connector. -

TheyStoppedit Replyezst036 said:Yes.

Nvidia properly shunted its 30x0 series cards. I still have not yet seen a melting connector with them. One probably does exist, maybe, to be fair.

The Asus 4090 Matrix are properly shunted. Not seen those have a melting connector either. The Asus 5090 Astral is also properly shunted to prevent a melting connector.

The Matrix and the Astral are not shunted to prevent melting. They are shunted to give you a warning in the event of imminent danger but have no additional safeties in place than any other card. You have to download their software. Once the warning is given, it is up to the user to take corrective action. However, there is absolutely ZERO additional protections. They only provide a warning message on the screen, that is it. If you start a big rendering task on your PC with an Astral/Matrix, then let it run while you sleep for 8 hours..... if there is danger while you're sleeping, the warning will come up. You won't see it because you are sleeping, the connector will melt like any other 90 cards. The Astral/Matrix ONLY provide a warning. That is it