Old hard drive modded into a variable speed disc sander, spinning rust sands things nicely

The motor probably only has enough torque for finer tooling and grinding projects.

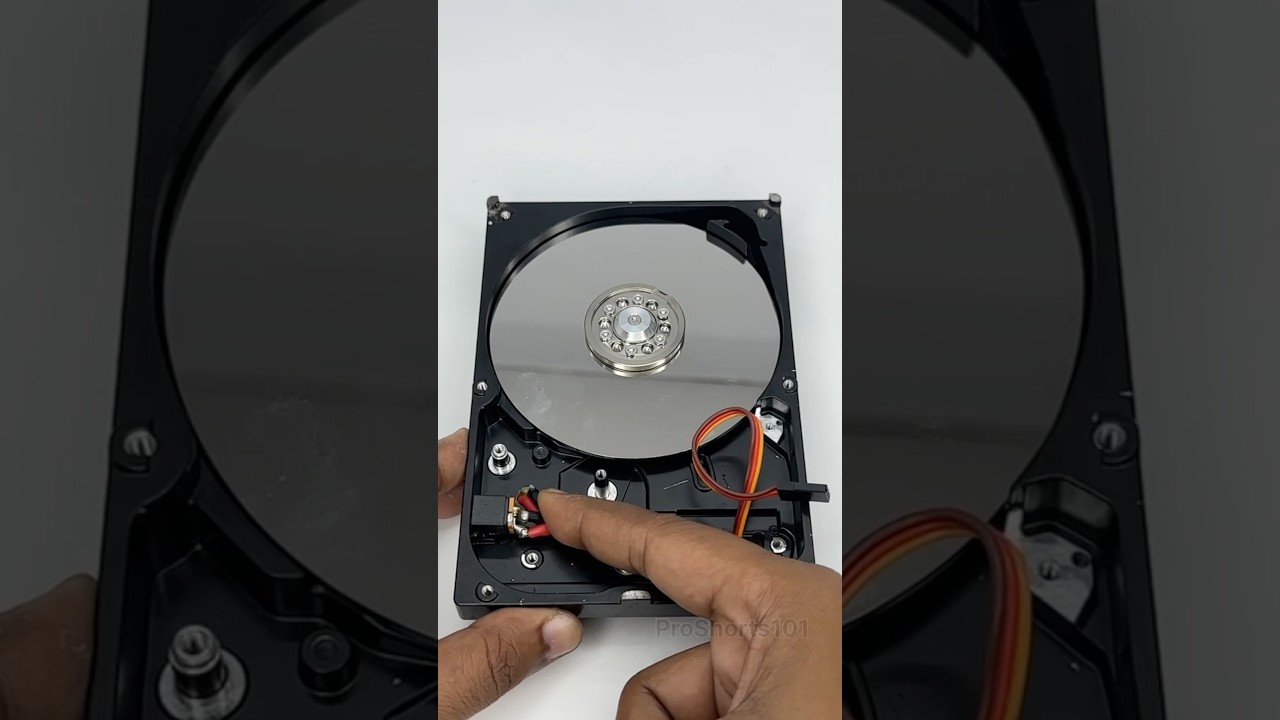

An enterprising individual has shared a quick step-by-step guide showing how to convert an old Hard Disk Drive (HDD) into a small but useful variable speed disc sander. The project also requires just a modicum of time, a few simple tools, and a handful of extra components.

If you have been a computing enthusiast for more than a few years, you might have a few unwanted or dead HDDs in your possession. You might also reckon that a disc sander is a useful tool to have, but do not feel that shelling out over $100 on a dedicated device, like this one on Amazon, is worth it. If these two planets align for you, then YouTuber ProShorts101's idea might be the perfect project.

The project starts with a WD Caviar Blue WD1600AAJS. This 2009 vintage HDD offered a meager 160GB of noisy spinning rust storage. We aren't sure if this particular WD1600AAJS was still functional as data storage, but would hope not, as that would upset the gods of retro. While the 7,200 rpm motor in this 3.5-inch device might be one of the better choices available for the intended task, here it is souped-up with a 30 Amp Electronic Speed Controller (ESC), among other components.

On the topic of components, according to ProShorts101, the following list of bits and pieces is required to transmogrify your HDD into a disc sander: an old HDD, a 30A Drone ESC, a servo tester, a 12V socket, and some sand paper.

HDD disc sander maker method

Start by disassembling the HDD, which means taking off the metal lid, removing the platter read heads and supporting assembly, and the drive controller PCB from the other side. Next, solder the ESC to the drive power pads, as shown in the video. You will then thread the ESC's cables to the front of the disc sander project. Wire up the 12V power socket and variable speed-enabling potentiometer circuit as shown.

For a clean build, ProShorts101 drilled cable routing holes, and cut and repurposed the metal lid so that only the spinning disc was exposed. This reworked lid helped secure the power socket and variable speed knob. Last but not least, it was time to cut out and mount the chosen abrasive to the spinning disc surface. ProShorts101 used lots of glue and a rough looking piece of what looked like aluminum oxide paper.

Some video viewers suggested a project-improving tweak where a Velcro surface could be added to the HDD disc, meaning a user could renew or switch sandpaper grades and types more easily.

Stay On the Cutting Edge: Get the Tom's Hardware Newsletter

Get Tom's Hardware's best news and in-depth reviews, straight to your inbox.

Finally, this upcycled HDD disc sanding tool will probably not be a serious rival to even the most budget-conscious devices available at retail. Nevertheless, it might be adequate for smaller scale tasks like sharpening nail scissors or reshaping small wooden spatulas.

Follow Tom's Hardware on Google News to get our up-to-date news, analysis and reviews in your feeds. Make sure to click the Follow button.

Mark Tyson is a news editor at Tom's Hardware. He enjoys covering the full breadth of PC tech; from business and semiconductor design to products approaching the edge of reason.

-

Hooda Thunkett A 30 Amp ESC? Are you sure? My car charger is hooked up to a 30 Amp circuit. That's a huge amount of current !Reply -

BillyBuerger Hmmm, this could be a fun project. I have some old 10k/15k SCSI/SAS drives that could be fun to try with.Reply -

Misgar Some hard drives use glass platters. Imagine what might happen if a platter breaks at 7,200RPM. Even more "fun" at 10,000 or 15,000RPM. Face mask anyone?Reply

https://external-content.duckduckgo.com/iu/?u=https%3A%2F%2Faesonlabs.ca%2Fwp-content%2Fuploads%2F2018%2F10%2Fshattered-platter-damage.jpg&f=1&nofb=1&ipt=8b8a7174c135360104eaa348b1b58c9c4aa4d2cab3b5fb132c32a47bdf36bad2 -

artk2219 Reply

Its fine, totally fine, see it has the sand paper that was attached to the top, its like extra reinforcement, or something lol.Misgar said:Some hard drives use glass platters. Imagine what might happen if a platter breaks at 7,200RPM. Even more "fun" at 10,000 or 15,000RPM. Face mask anyone?

https://external-content.duckduckgo.com/iu/?u=https%3A%2F%2Faesonlabs.ca%2Fwp-content%2Fuploads%2F2018%2F10%2Fshattered-platter-damage.jpg&f=1&nofb=1&ipt=8b8a7174c135360104eaa348b1b58c9c4aa4d2cab3b5fb132c32a47bdf36bad2

Thats what i was thinking, thats a ton of power for such a small motor. I mean i guess if its what you have on hand, still seems like overkill though.Hooda Thunkett said:A 30 Amp ESC? Are you sure? My car charger is hooked up to a 30 Amp circuit. That's a huge amount of current ! -

Eximo Reply

30 Amps at the low voltage side, not the AC side. 6.6kW would make that explode, instantly.Hooda Thunkett said:A 30 Amp ESC? Are you sure? My car charger is hooked up to a 30 Amp circuit. That's a huge amount of current !

So like, maybe 100W to the motor at 3.3V? Still high, not sure what voltage the spindle runs at.

Also, they gave that for the controller's power rating, not necessarily what was sent to the motor. -

Sippincider Reply

Shattered grinding wheels are a reality and nothing to mess around with. IMO repurposing high-speed platters into something they were never remotely designed for is venturing into Darwin Award territory.Misgar said:Some hard drives use glass platters. Imagine what might happen if a platter breaks at 7,200RPM. Even more "fun" at 10,000 or 15,000RPM. Face mask anyone? -

CelicaGT Guys, the ESC is capable of delivering 30A (peak, burst), that's it. The actual current draw will likely be what it was before this thing became a questionable power tool, depending on the voltage used and the mechanical load from "grinding".Reply -

mike.stavola I would be happy to run this at, like, 10k rpm or lower, with a shield around the edge to catch the exploded platter.Reply

I know enough about this by experimenting with something like this a long time ago. Turns out, when you apply pressure to a spinning drive platter (at 50-70k RPM), it can unexpectedly explode with enough force for the shrapnel to pierce 16ga sheet steel. -

snemarch Reply

It's scary enough when a tiny dremel grinder bit shatters – I definitely wouldn't mess around with repurposing hard-drive glass platters for something like this 😬Sippincider said:Shattered grinding wheels are a reality and nothing to mess around with. IMO repurposing high-speed platters into something they were never remotely designed for is venturing into Darwin Award territory.