Thermal Paste Comparison, Part One: Applying Grease And More

If you find yourself fighting a stubbornly-low overclock, there's a chance that your thermal solution isn't working as effectively as it should. We're testing a number of thermal pastes that might help. But first, let's go over the basics of CPU cooling.

Choosing The Right Paste: More Than A Matter Of Price

Because thermal paste is a high-margin product, the market is crowded. While the exact composition of most products is a well-kept secret, a Google search makes it pretty easy to get a list of typical ingredients. The upper temperature limit is typically 150 °C, though some pastes claim to withstand up to 300 °C or more.

The composition of a paste determines its thermal conductivity, its electrical conductivity, its viscosity, and its durability. But what is a paste really made of? Basic compounds consist of zinc oxide and silicone as a binding agent. However, such simple combinations are barely sold anymore. Most vendors start with these ingredients and add other materials, like aluminum. Case in point, the Prolimatech PK1 sports 60-85% aluminum content, 15-25% zinc oxide, and 12-20% silicone oil, as well as an anti-oxidation agent. Some ingredient lists are more mysterious. For instance, the one printed on be quiet!'s DC 1 syringe ambiguously specifies 60% metal oxide, 30% zinc oxide (wait a second; since when is zinc not a metal?), and 10% silicone.

Some pastes, like Arctic Silver 5, even contain silver. Other pastes are based on graphite, like the professional-grade WLPG 10 by Fischer Elektronik, forego the silicone, and claim very high thermal conductivity (10.5 W / m·K), but they are more difficult to apply and are typically electrically conductive. There are also pastes that employ carbon nanoparticles, though they're not suitable for most enthusiasts due to their electrical conductivity and price. The number of copper-based pastes on the market has shrunk, but if you search, you can still find a few.

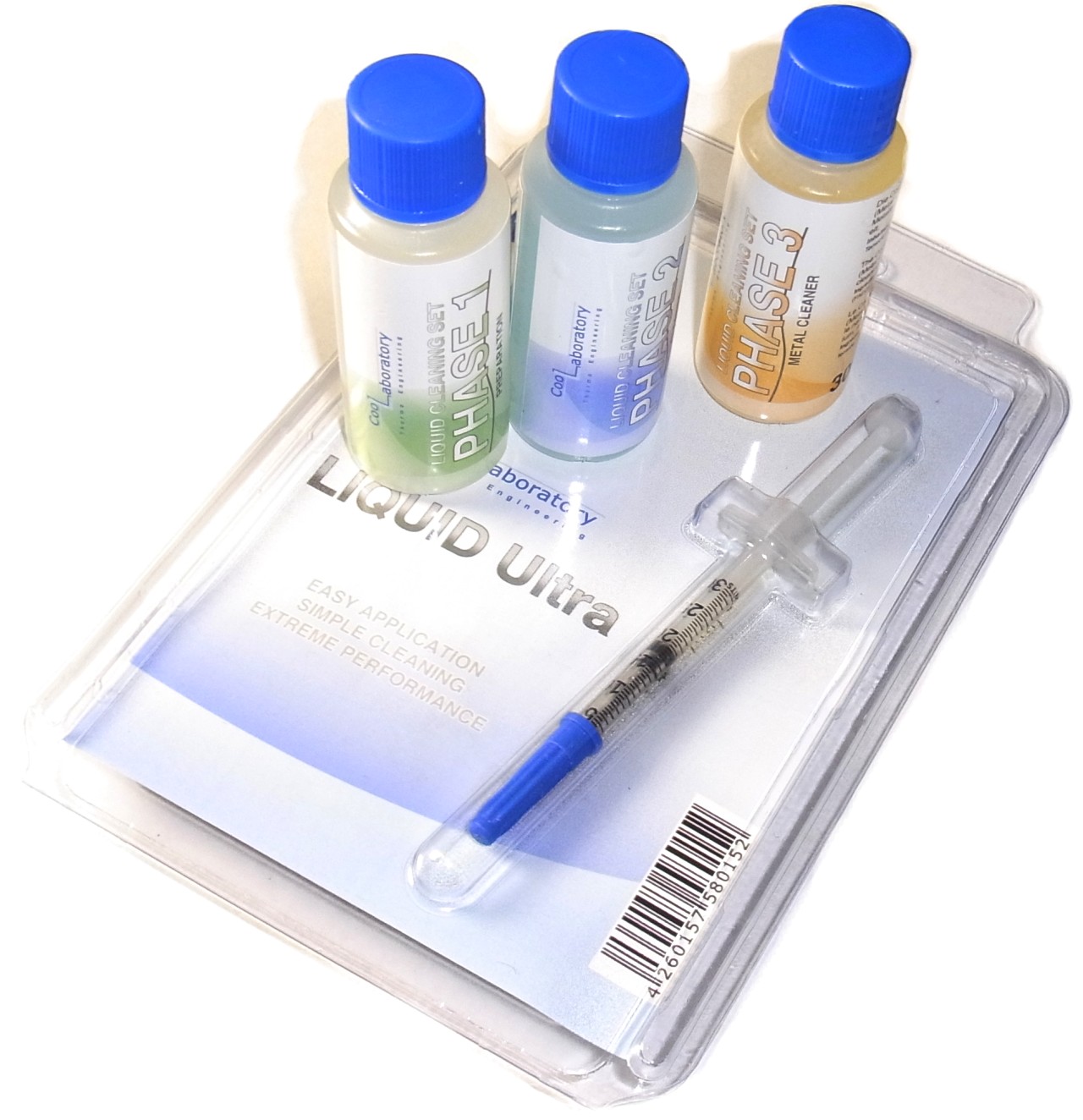

I leave the more exotic thermal coupling solutions like liquid metal and metal pads for the second part of our tutorial. Applying these electrically conductive products is not without risk, and I don’t want to confuse anyone with a detailed discussion of them at this point. Let’s just say that they're for expert use only, and you'll want to satisfy a few prerequisites prior to applying them.

All pastes share one thing in common: regardless of their composition or price, they all fall short of heat sinks and spreaders with regard to thermal conductivity. Thus, a thermal paste is always the weakest link in the cooling chain, regardless of its price!

Current page: Choosing The Right Paste: More Than A Matter Of Price

Prev Page The Differences Between AMD And Intel Heat Spreaders Next Page Applying Thermal Paste, Part OneStay On the Cutting Edge: Get the Tom's Hardware Newsletter

Get Tom's Hardware's best news and in-depth reviews, straight to your inbox.

-

alidan please tell me yo are also going to do the solder the heatsink to the cpu method? i forget what its called, but that is what i want to use for my next computer and would love to see how it stacks up.Reply -

The Von Matrices In the second section about advanced cooling methods, are you planning on discussing delidding CPUs and replacing thermal paste? If you do it might be worth mentioning that the delidding won't improve temperatures because of improved thermal paste conductivity but because of reducing the thickness of the paste. See http://forums.anandtech.com/showpost.php?p=34053183&postcount=566Reply -

stickmansam Huh, I do turn my heatsinks sometimes for optimal alignment so the heat pipes are perpendicular to the die. Depends if I got the room in the case and what ram is being used. Also heatsink dependentReply -

slatts1024 One of the best articles I've read on Tom's in years and that's saying something. Looking forward to part 2.Reply -

Shankovich Loving that DHT-based design overlay picture on the first page. I've been telling my friends for a while to just get coolers with plated covers because the pipes miss the hotspot on intel CPU's, but no I'm full of bs apparently. This video is awesome btw, shows how spreads happen http://www.youtube.com/watch?v=EyXLu1Ms-q4Reply -

nukemaster How many volts does this "7 volt" unregulated power supply put out?Reply

Just curious. I have some 8/9/12 volt regulators that would eliminate the guessing games for resistor fan adapters(voltage depends on the fans current draw).

I have seen unregulated 6 volt power supplies range from 8-over 12 volts at low loads.

For a rather low price you can use a regulator to get whatever voltage you want :)

ohh yeah and...

I can't wait for the next part of this to be release -

jimmysmitty From what I have seen it depends on the materials. AS5 was great for a while but thee are better ones out than that now such as Noctuas or Zalmans.Reply

I also enjoyed using the IC Diamond thermal paste as it proved to cool very well but since it has a diamond based substance it can scuff the heat spreader.