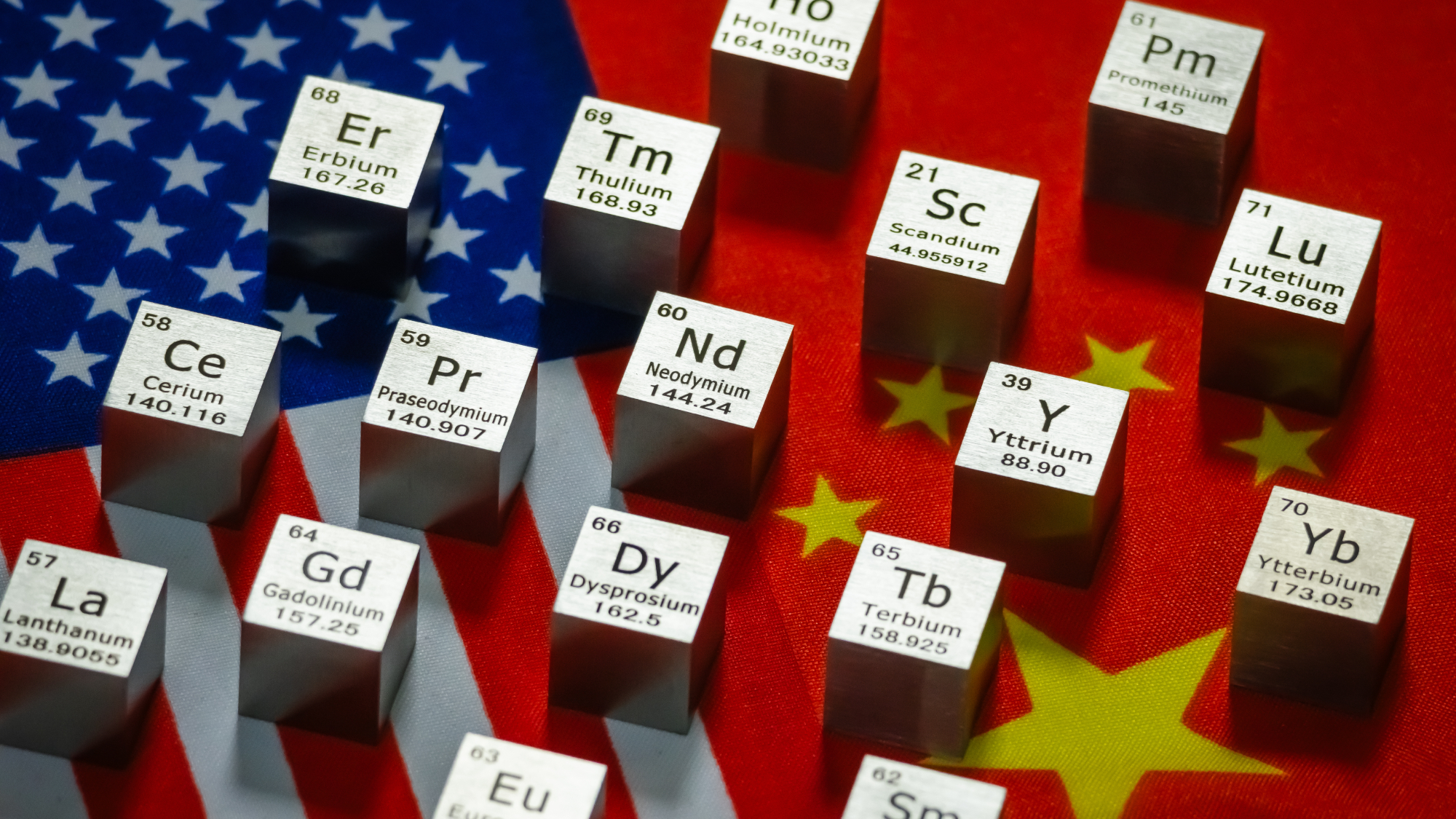

1,500% price increase on some rare earth elements squeezes chipmaking business — Yttrium surge caused by trade war between U.S. and China

Prices have gone through the roof, surging from $8 to $126 per kilogram in under 12 months.

The price of the rare earth element Yttrium has jumped through the roof, with a kilogram of the material currently sitting at $126 per kilogram. According to Bloomberg, this resource cost less than $8 at the end of 2024, meaning its price has increased by nearly 1, 500% in the past 12 months. This is an all-time high for Yttrium, with the trade war between the U.S. and China fueling the price hikes. This material is crucial for semiconductor manufacturing, where it’s used in various processes, including thin-film deposition and wafer polishing.

While there has already been some brewing rivalry between Washington, D.C., and Beijing, it came to a head in April when U.S. President Donald Trump imposed tariffs on all of the U.S.’s trading partners. This has led to an escalation between the East and the West, culminating in a 145% tariff on Chinese goods entering the United States and a reciprocal 125% import levy for American products landing on China’s shores.

The two parties eventually started trade negotiations, which resulted in the lifting of these threats. It seemed that progress was being made at the negotiating table, but China suddenly put strict export controls on rare-earth materials in early October. This move could gravely impact the global semiconductor supply chain, and Trump responded by threatening a 100% tariff on all Chinese goods and a far more devastating critical software ban. The two parties eventually realized that such a move would not do anyone good, so they agreed to a one-year tariff truce, resulting in China suspending its more recent rare-earth export control measures. However, the April ban on some rare earth exports to the U.S. remains, meaning supply remains tight.

Because of this, Yttrium prices continue to creep higher, even as the U.S. and its allies seek alternative sources. At the moment, more than 90% of the rare earth metals that the U.S. needs are sourced from China, but it’s working on expanding its own domestic source from the Mountain Pass project in California. Trump is also considering allocating $2 billion in CHIPS Act funds to the critical minerals supply chain to help bolster its resiliency. Australia is also working on extracting more rare earths from its mining waste, while Canada is looking to open a new rare earths mine in its Critical Mineral Strategy Annual Report 2024.

Follow Tom's Hardware on Google News, or add us as a preferred source, to get our latest news, analysis, & reviews in your feeds.

Get Tom's Hardware's best news and in-depth reviews, straight to your inbox.

Jowi Morales is a tech enthusiast with years of experience working in the industry. He’s been writing with several tech publications since 2021, where he’s been interested in tech hardware and consumer electronics.

-

yaitanes Reply

not yet, but we're getting there. Then so what? it would still have to be sent to china to process. All processing tech and machineries are export controlled by china. Assuming one can get hands on those machines and tech then you still need chemical reagents which still made in china at scale. Now one just need the machines and tech to make those chemical reagents..... now has to train an army of people in rare earth tech to make those chem and operate machineries. Now where can one find 20.000 yearly rare earth tech graduates? oh china has them! oh well!George³ said:It is now profitable enough to mine even in countries with high wage costs?

p/s: good luck with getting a mining license in less than 10 years -

George³ Reply

I assume that countries have already mined such elements before a huge part of their production was shifted to China because of the price. So there are already discovered deposits, some of which are developed. There are facilities and specialists. There is also production of all the necessary reagents and catalysts for the process of extracting the elements from the ore. Yes, they have not worked for decades and it will take some effort to bring them back into operation, but...yaitanes said:not yet, but we're getting there. Then so what? it would still have to be sent to china to process. All processing tech and machineries are export controlled by china. Assuming one can get hands on those machines and tech then you still need chemical reagents which still made in china at scale. Now one just need the machines and tech to make those chemical reagents..... now has to train an army of people in rare earth tech to make those chem and operate machineries. Now where can one find 20.000 yearly rare earth tech graduates? oh china has them! oh well!

p/s: good luck with getting a mining license in less than 10 years -

BFG-9000 The primary consumer product use of Yttrium nowadays is in white LED phosphors, since gas mantles and multiple rare earth type TIG tungstens (like E3, LaYZr, TriMix) aren't exactly big sellers anymore. You could even go back to radioactive Thorium for the latter two uses, as was used in the olden days.Reply -

bill001g Reply

The wage cost is only a tiny part of the problem. The bigger issue is all the different group lining up trying to prevent any mining. They complain about anything from some rare insect that will be wiped out or that the land has some historic native american meaning. They use their cell phones that are made with the same rare earth while they sit and protest. For whatever reason they don't care that china mines this stuff with much less regulation than the USA. If they really cared they would protest the use and sale of devices that caused all this environmental harm.George³ said:It is now profitable enough to mine even in countries with high wage costs?

It is hard to say if this is real or not. There is huge money backing this opposition. They pay for lots of expensive lawyers to file lawsuit after lawsuit to slow things down even when they know they are going to lose. Some of these protesters are also being paid. Me wearing my tin foil hat would say the larger business in china are behind this to keep their advantage.