Intel shares biggest unboxing video ever as ASML’s $380 million High-NA lithography machine is installed in Oregon fab

Video shows the machine going from cargo plane, to truck, to its home in Intel’s Oregon fab.

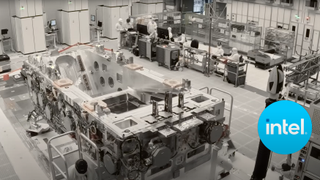

Late last year, ASML began shipping its first high-NA extreme ultraviolet (EUV) lithography system to Intel, and this past weekend, the processor giant published a video covering the installation of the tool into its fab near Hillsboro, Oregon. The machine will be used primarily for research and development purposes.

ASML's Twinscan EXE:5000 High-NA EUV machine is indeed absolutely massive. In total, 250 crates are required to transport the machine, which weighs in the neighborhood of 330,000 pounds.

A cargo plane transported the container in the video from The Netherlands to Portland, Oregon, and then a truck delivered one of the key components of the tool. As you can see in the video below, the unit has been installed at the fab, but it will take 250 ASML and Intel engineers about six months to install the machine completely.

But even when the Twinscan EXE:5000 High-NA EUV machine is fully assembled, ASML and Intel engineers will still need to calibrate it. This will take weeks if not months. At first, the two companies will have to 'light up' the device, which is when photons hit resist on wafers, which ASML engineers recently achieved with their High-NA EUV tool in Veldhofen, the Netherlands.

ASML's High-NA EUV Twinscan EXE tool can print at an 8nm resolution, significantly enhancing the performance of currently used Low-NA EUV scanners, which are limited to 13nm resolution with a single exposure. This advancement enables building transistors that are about 1.7 times smaller than today, resulting in almost triple the transistor density. Achieving 8nm critical dimensions is crucial for producing chips using sub-3nm process technologies, a target the industry hopes to reach between 2025 and 2026.

Intel will use its Twinscan EXE:5000 lithography tool mainly to learn how to use High-NA EUV technology. The company plans to test the usage of High-NA lithography with its Intel 18A process technology (albeit not for high-volume production) and eventually adopt it for high-volume manufacturing with its Intel 14A fabrication process.

ASML previously announced that its next-generation High-NA EUV chipmaking tool would be more than double the price of its current Low-NA EUV lithography tools, or approximately $380 million (€350 million). However, the exact price will depend on the actual configuration of the device — Intel CEO Pat Gelsinger recently said the machine cost '400-ish million.'

In comparison, existing Low-NA Twinscan NXE EUV systems are priced at around $183 million (€170 million), with variations based on specific models and configurations. Intel may be the first to receive this cutting-edge fabrication tool, but ASML has disclosed “10 to 20” orders for its High-NA EUV machines from companies like Intel, Samsung, SK Hynix, and TSMC.

Stay On the Cutting Edge: Get the Tom's Hardware Newsletter

Get Tom's Hardware's best news and in-depth reviews, straight to your inbox.

Anton Shilov is a contributing writer at Tom’s Hardware. Over the past couple of decades, he has covered everything from CPUs and GPUs to supercomputers and from modern process technologies and latest fab tools to high-tech industry trends.

-

darenn I'm sure there are time lapse videos of bigger and more expensive machines being "unboxed". Unless you mean "biggest" for Intel.Reply -

JTWrenn I love that they showed this. The general populous should see more about how all of this is done to understand how damn hard it is. Intel seems to have finally woken up to the idea of being a customer facing company a bit with pr being a much bigger part of what they do. Hope they keep it up.Reply -

Steve Nord_ I gave a semiconductor maker I hardly ever use but maybe $8B and all I got was this i5 news.Reply -

brandonjclark I watch videos like that and I just feel stupid. Like, I could NEVER create something like that.Reply

Then I remember that it was created by so many people all doing their small part.

At times humanity can be so impressive.

Most Popular