Purported TSMC engineer boasts of recent 6% boost to 2nm yields, passing 'billions in savings' to customers (Updated)

The higher, the better.

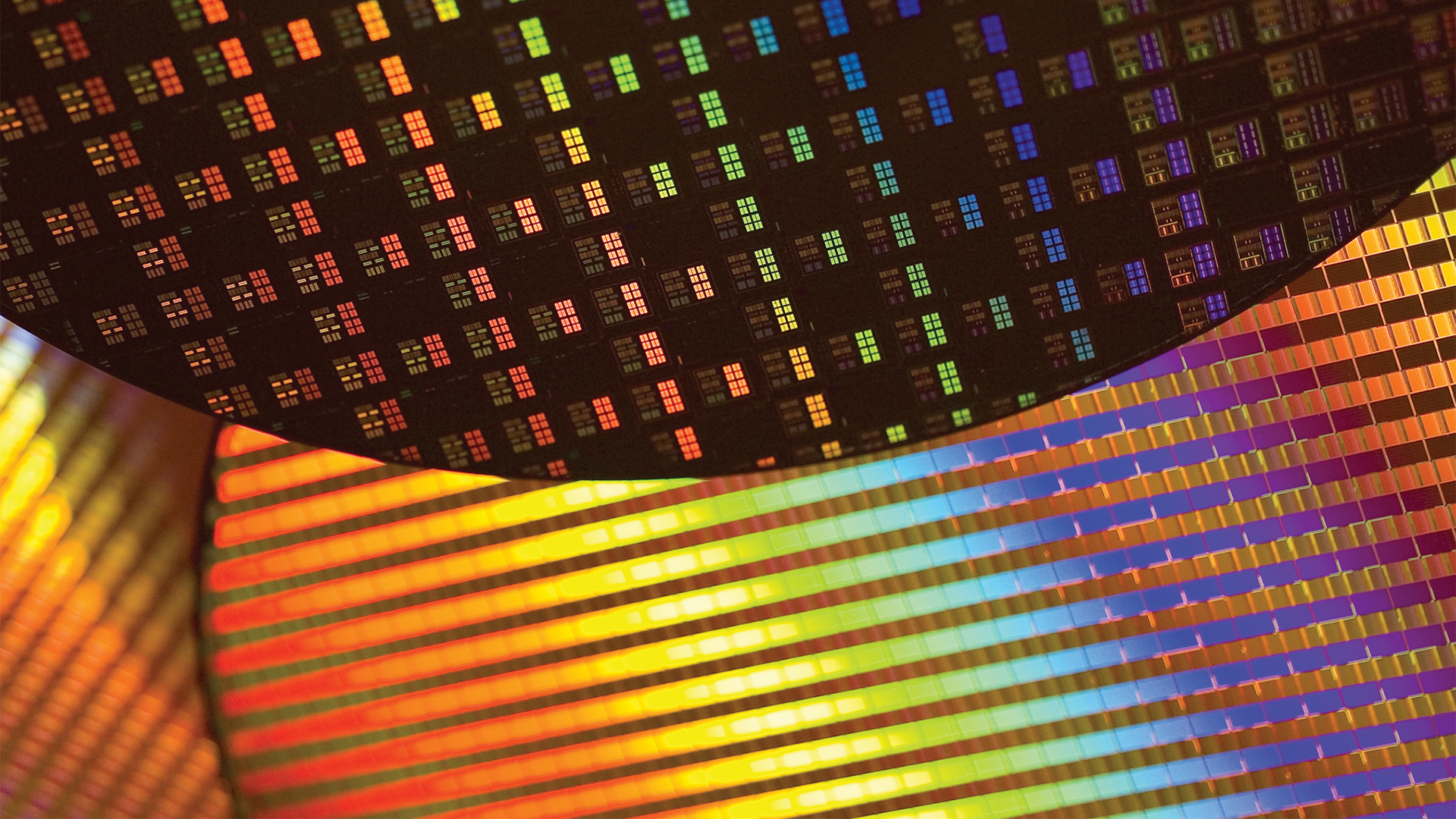

TSMC is set to start mass production of semiconductors using its N2 (2nm-class) fabrication process sometime in the second half of next year, and right now, the company is doing its best to polish off the technology in terms of lowering variability and defect density and therefore improving yields. Rumors are already flying about the progress on the node, and one recent tweet from a purported TSMC engineer (the tweet and unverified account were deleted a day later) went semi-viral, garnering plenty of attention on X (formerly Twitter). The purported TSMC employee said the team has managed to increase yields of the 2nm process by 6%, 'creating billions in savings' for the company's customers.

The purported TSMC employee, who calls themselves Dr. Kim, did not reveal any of the key details, such as whether the foundry improved yields of SRAM test chips or logic test chips yields, so you should take the claims with a grain of salt. Keeping in mind that TSMC will only begin offering its shuttle test wafer services for 2nm technology in January, it is unlikely that the contract chipmaker could improve yields for prototypes of actual chips that will eventually be made at 2nm.

I increased the yield of our 2 nm process by 6% creating billions in savings for our customers https://t.co/eoyJRRHA4VDecember 1, 2024

Sizable improvements in yield certainly aren't unheard of early in the node development process, and improving yields of SRAM and logic test chips is indeed very important as, eventually, it can translate to significant savings for customers who pay for wafers and, therefore, benefit from higher yields.

TSMC's N2 will be the company's first fabrication process to use gate-all-around (GAA) nanosheet transistors that promise substantial power reduction, performance boost, and transistor density. In particular, TSMC's GAA nanosheet transistors are not only smaller than 3nm FinFET transistors, but they enable smaller high-density SRAM bit cells by offering improved electrostatic control and reducing leakage without compromising performance. Their design enhances threshold voltage tuning, ensuring reliable operation and allowing further miniaturization of logic transistors and SRAM cells. Yet, TSMC will have to learn how to produce all-new transistors with decent yields.

Chips manufactured using N2 fabrication technology are projected to consume 25% to 30% less power at the same transistor count and frequency than chips made on N3E manufacturing node, deliver a 10% to 15% performance improvement with the same transistor count and power, and offer a 15% increase in transistor density while maintaining equivalent speed and power compared to semiconductors made on N3E.

TSMC is expected to start mass production of chips on its N2 fabrication process sometime in the second half of 2025, likely in late 2025. To that end, the world's largest contract maker of chips has plenty of time to improve yields and reduce defect density.

Edit 12/4/24 4:00am PT: Clarified details of purported employee and account deletion.

Get Tom's Hardware's best news and in-depth reviews, straight to your inbox.

Anton Shilov is a contributing writer at Tom’s Hardware. Over the past couple of decades, he has covered everything from CPUs and GPUs to supercomputers and from modern process technologies and latest fab tools to high-tech industry trends.

-

spongiemaster Reply

I'm so happy for Apple. It's the holidays, I'm sure they need the money to buy Xmas presents.Admin said:Improving TSMC's N2 yield by 6% could save billions for its customers, says employee.

TSMC engineer boasts of recent 6% boost to 2nm yields, passing 'billions in savings' to customers : Read more -

dalamite Reply

I read very recently that AMD will also be using N2 note initially alongside of Apple. AMD is at least more likely to pass the savings onto the consumers, but with Intel sucking so much these days, AMD might have no incentive to drop prices.spongiemaster said:I'm so happy for Apple. It's the holidays, I'm sure they need the money to buy Xmas presents. -

mac_angel "customers" meaning the companies that buy those from TSMC. The end user customers definitely do NOT see any savings.Reply -

A Stoner I did the same thing for a defense contractor on a physical part once and got layed off almost immediately after.Reply

I increased their yield from <1% to >92% while reducing the production cost of each attempt by about 40% and increased performance of the item by 32%.

Hope this guy fares better and gets a promotion! -

A Stoner Reply

Eventually you could see savings. Competition still exists in many places and that means if the builder can save some cash in one area, and wants more of the market, the best place to do that is lowering prices and ensuring product availability.mac_angel said:"customers" meaning the companies that buy those from TSMC. The end user customers definitely do NOT see any savings.

If you have not noticed, lack of product availability is where much of the inflation in things like video cards come from. So, having higher yields will result in 2 forms of cost savings, one that can be seen in MSRP if the seller so chooses, and the other is in market availability which can lead to more MSRP sales prices as well as potential sales. -

cpdx7 Wow I am amazed at the low journalistic quality here, this article literally says nothing, or nothing more than stating that the sky is blue. TSMC will have to increase yields dramatically in order to be production worthy. A 6% change at this point is to be expected and run-of-the mill. At this point, yields will need to improve a LOT more than 6% to become production worthy.Reply